Effect of filler loading on Mechanical properties of NR, NR/BR and NR/SBR blends cured in a vulcanization system

ABSTRACT

In this work the mechanical properties of three types of dough rubber have been investigated; every one of these types used five percentages of the materials filler: (30, 40, 50, 60 and 70) pphr. The samples were made and prepared in the laboratories of the public company of tires Babylon in Al-Najaf.

The effects of filler loading on the tensile, compression, fatigue (crack growth) and hardness properties of NR Dough, NR/BR and NR/SBR blends using a vulcanization system were studied. Carbon black (N326) was used as a filler and the loading range was from 30 to 70 pphr.

To determine the tensile strength, M300 (tensile stress at 300% elongation) and elongation at break a tensile test device called (Tensilmete) was used According to ASTM D412, operating at different strain rates of (100, 200, 300, 400, 500) mm/min.

Results show that for the blends, tensile strength and M300 increases, but elongation at break decreases with filler loading (carbon black) increased. For a fixed filler loading, NR dough consistently exhibits higher tensile strength and M300 and lower elongation at break compared to NR/BR and NR/SBR blends. The maximum value of tensile stress at NR dough (carbon black 60 pphr) reaches 23.2 MN/m2, and maximum tensile strain at NR dough (carbon black 50 pphr) reaches 805.5% , and maximum Young's Modulus of 300% elongation at NR dough (carbon black 70 pphr) reaches 4.3 MN/m2.

The compression test (ASTM D395B) shown that the compression is decreased when the percentages of carbon black is increased and the maximum value of compression set at NR dough (carbon black 30 pphr) reaches 29.3%.

Fatigue (Crack Growth) test was according to ASTM D 813 for rubber testing. The minimum value of fatigue (crack growth) at NR dough (carbon black 30, 40, 50 hpr) reaches 3.5 mm at the number of cycles is constant (15000 cycles).

The maximum value of Hardness at NR dough (carbon black 70 hpr) reach to 68 [IRHD].

Finally, by using a device (Rheometer), it was found that the crosslinks density of NR/SBR dough is better, compared with that of NR and NR/BR blends.

The mechanical properties of natural rubber change because of a change in the proportion of the impurities in it, and the degree of crystallinity, which varies with temperature as natural rubber crystallizes when the temperature is within the [10Co], where the density changes from 92% to 59% gm/m3 depending on the temperature and also higher molecular weight rubber as the volumetric expansion coefficient is almost [0.00062m3]. Reinforcement of elastomeric compounds, defined as the simultaneous enhancement of the elastic modulus and the elongation at break, by addition of particulate filler, is probably one of the most important phenomena in material science and technology.

The increase in stiffness imparted by the filler particles involves a hydrodynamic effect which depends on the filler volume fraction, but the occlusion of rubber by the aggregate and the rubber trapped within the filler agglomerates may increase the effective filler volume. On the other hand, the shape factor (anisometry) also contributes to the increase in moduli [1]. Nevertheless, the most important contribution to the elastic modulus arises from polymer/filler interactions which can be increased if a good dispersion of the filler is achieved. These interactions depend on the surface characteristics of the particles (active sites and surface free energy) and also on the chemical nature of the polymer. Polymer–filler interaction leads to immobilization of chain segments on the filler surface whose mobility is reduced with regard to that of the polymer matrix. It will result in a rubber shell in a quasi-glassy state with a thickness depending on the polymer–filler interaction and also on the surface area of the filler. Consequently filler surface chemical characteristics and its particle size may be considered as factors influencing the effective volume of filler [2]. Elastomers are very unique material. During processing and shaping, it behaves mostly like a highly viscous fluid. After its polymer chains have been cross-linked, by vulcanization (or by curing), elatomers can undergo large reversible elastic deformations. Unless damage occurs, it will return to its original shape after removal of the load. Fillers are usually added to elastomers (dispersed in a network of polymeric chains) to enhance their mechanical properties, e.g. fillers are added to rubber products such as car tires and shock mounts to enhance their stiffness and toughness properties. An elastomer contains filler materials usually called filled elastomer, and called unfilled elastomer if without fillers. The most commonly used fillers are: carbon black and silica. The carbon particles range in size from a few hundred to thousands of angstroms. They influence the dynamic and damping behaviour of rubber in a very complex and non-proportional manner. The unique behaviour of carbon black-filled elastomers results due to a rigid, particulate phase and the interaction of the elastomer chains with this phase [3].

In this work, you prepare three doughs of the Elastomeric materials, for each material the tests are performed on specimens containing a range of different carbon black filler concentrations.

The rubbers (Elastomers) used in this study, i.e. NR (Natural Rubber), BR (Polybutadiene Rubber) and SBR (styrene-butadiene rubber 1502) were supplied by the laboratories of the public company of tires Babylon in Al-Najaf. Carbon black (N330) was obtained from same company too.

The loading of these three fillers was varied from 30 to 70 pphr.

The rubbers were preblended and the mixing procedure described by the American Society for Testing and Materials ASTM D 3184-89 was followed. A typical formulation of the rubber compound is shown in Table (1). Rubber mixing was done by using a two-roll mill maintained at 70±5°C. The sheeted rubber compound was conditioned at 23±2°C for 24 h prior to cure assessment on a Monsanto Moving Die Rheometer (MDR 2000) at 185 °C.

Table (1) A typical formulation of the rubber compound. [4]

Ingredient |

NR Dough (pphr) |

NR/BR blend (pphr) |

NR/SBR blend (pphr) |

NR (Natural Rubber) |

100 |

50 |

50 |

BR (Polybutadiene) |

- |

50 |

- |

SBR (Styrene-Butadiene Rubber) |

- |

- |

50 |

Zinc oxide |

5 |

5 |

5 |

Streaic Aid |

2 |

2 |

2 |

Carbon black (N-326) |

Variable |

Variable |

Variable |

P-oil |

7 |

7 |

7 |

6PPD |

3.25 |

3.25 |

3.25 |

Mic. Wax |

2 |

2 |

2 |

Sulphur |

1.8 |

1.8 |

1.8 |

MBS |

0.8 |

0.8 |

0.8 |

CTP-100 |

0.13 |

0.13 |

0.13 |

3.1 Tensile Test

3.1.1 Tensile Strength:

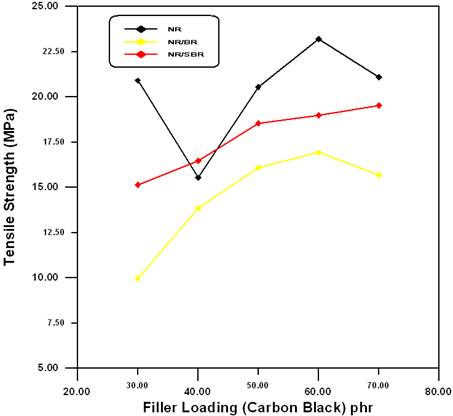

The effect of filler loading and type on tensile strength of NR, NR/BR, NR/SBR blends is shown in Figure (1). It can be seen from figure that the tensile strength for carbon black-filled NR, NR/BR, NR/SBR blends increases with increasing filler loading (carbon black). The carbon black (N326) has large surface area. It is well known that the larger the surface area of particulate filler, the greater the interaction between the filler and rubber matrix. Tensile strength can be further increased within limits with increase in crosslink density or at constant crosslink densities by addition of carbon. It is noted the tensile strength decreases in NR dough at carbon black 40 pphr. Thus might be due to way of dough perpetration because the mill was at high temperature leading to partial vulcanization. The comparison of tensile strength of NR, NR/BR, NR/SBR blends at 30, 40, 50, 60, and 70 pphr of filler loading is shown in Figure (2). It can be seen that for all fillers, the tensile strength for NR is higher than that for NR/SBR and NR/BR blends. This observation might be better for filler–rubber interphase interaction in NR blends compared with NR/SBR and NR/BR blends.

Figure (1) Variation in Tensile strength with carbon black for the NR, NR/BR, and NR/SBR blends.

3.1.2 M300 (tensile stress at 300% elongation):

Figure (3) shows that the effect of filler loading on M300 (tensile stress at 300% elongation) of NR, NR/BR, and NR/SBR blends. Figure (3) indicates that M300 for carbon black-filled, NR/BR, and NR/SBR blends increases with increasing filler loading (carbon black). M300 is affected by several factors such as surface reactivity which determines the polymer–filler interaction, aggregates, size and shape of particles, structure and filler particle dispersion in rubber ([5], p. 342; [6]). For carbon black, the interaction between filler and hydrocarbon rubber is stronger than its attraction between aggregates. [7] Also, as mentioned earlier, carbon black has larger surface area than any other filler. Figure (4) shows the comparison of M300 of NR, NR/BR, NR/SBR blends at 30, 40, 50, 60, and 70 pphr of filler loading. NR/BR blends exhibits higher M300 than NR and NR/SBR blends. From this observation, it is obvious that the ability of natural rubber reinforcement-as indicated by the former rubber blend-and a better rubber-filler interphase interaction are the two important factors in determining the strength of filled rubber-rubber blends.

Figure (3) Variation in M300 with carbon black for the NR, NR/BR, and NR/SBR blends.

Figure (4) Comparison of M300 among NR, NR/BR, and NR/SBR blends for carbon black of filler at 30 to 70 pphr loading.

The dependence of elongation at break of NR, NR/BR, and NR/SBR blends on the filler loading (carbon black) is shown in Fig. (5). It is obvious that elongation of at all blends break decreases gradually with increase in the filler loading (carbon black). So the carbon black-filled blends show a slightly lower elongation at break. Figure (6) compares the elongation at break among NR, NR/BR, and NR/SBR blends at 30, 40, 50, 60, 70 pphr filler loading (carbon black). For each type of filler, NR/BR, NR/SBR blends consistently exhibit lower elongation at break compared to NR Dough.

Figure (5) Variation in elongation at break with carbon black for the NR, NR/BR, and NR/SBR blends.

Figure (6) Comparison of elongation at break among NR, NR/BR, and NR/SBR blends for carbon black of filler at 30 to 70 pphr loading.

Figure (7) represents the results of compression set by the constant deflection for the standard vulcanized rubber and five other percentages of carbon black which were added to the rubber in (30, 40, 50, 60, 70), shows that the compression set is decreasing proportionally with increasing the percentages of carbon black .

Figure (7) show the effect loading filler (30 to 70 CB) on compression set C% for NR, NR/BR and NR/SBR blends.

Figure (8), (9) and (10) show the values of the crack growth test to the vulcanized rubber and refers to the increased crack length when the number of cycles and the percentages of the carbon black are increasing. This means that a crack does grow more carbon black is added.

Figure (8) The crack length against number of cycles for NR doughs.

Figure (9) The crack length against number of cycles for NR/BR blends.

Figure (10) The crack length against number of cycles for NR/SBR blends.

It is noted from Figure (8) that the crack length at the 3000 cycles for NR increases with carbon black ratio increase, at NR 70 dough separately. Also it is noted that the crack length nearly convergence between the NR 50 and NR 60 nearly.

It is noted from figure (9) that NR/BR blends there are imparity between crack length and ratios of carbon black in 3000 to 15000 cycles.

It is noted from figure (10) that the crack length converges at 3000 cycles and whenever the number of cycles increases spacing increases.

The crack length reduces in the three doughs with the NR dough has the least crack length and NR/BR blend and finally NR/SBR blend. We take advantage of this test to define the best dough endurance loads, and NR dough used in the manufacture of the (Side wall) and the (Tread) of the car tires, which are subjected to more cracks then any region in the tire.

Figure (11) shows the values of the hardness test to the NR, NR/BR, NR/SBR blends of rubber and show increase in the hardness when the percentages of the carbon black are increasing. This means that a hardness property is improved when the carbon black is added.

These results were taken from the special chart of the Rhrometer test [8], which was printed after the test was finished and the figure (12) show the result test o NR (30CB):

There fifteen charts for all the Dough NR, NR/BR and NR/SBR but you choose carbon black ratio 30 pphr for analyzed.

In the figure (12) the torque with vulcanization time for NR dough, at a temperature of 185. Note the increase in torque in the first minute, until it reaches the maximum value (lb-in) in 3 min, and then declines slightly in the remaining three minutes to be nearly stabilized.

REFERENCES

Source: http://uokufa.edu.iq/staff/zaidga/research/paper%20(Rewriter).doc

Web site to visit: http://uokufa.edu.iq

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes