There are several types of fasteners used to join pieces of sheet metal and to attach sheet metal to other materials. This chapter will cover the commonly used types of fasteners, their characteristics and standard designation and the various types of welding used in sheet metal work.

Before modern welding techniques came into common use, riveting was one of the most common methods for joiing sheet metal. Since the advent of the new welding techniques and modern machines that form seams on sheet metal, riveted seams are not so common in modern sheet metal work. However, the sheet metal worker will often use rivets on sheet metal too heavy for machine forming and where welding is not practical.

Rivets may be made from steel, copper, brass, aluminium or other materials. Standards for rivets sizes and shapes have been put forward by several agencies.

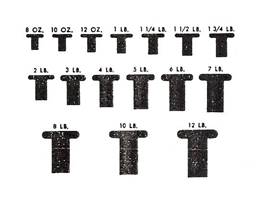

They are small flat headed rivets with relatively short lengths. The size number of tinman’s rivets are determined by the approximate weight per thousand rivets. Each weight of rivet has a definite diameter and length.

Figure 2 - Tinman's Rivets

Riveting may be done by hand or by machine. When the job is performed by hand, as is usually the case in sheet metal work, it is done with a hammer and rivet set.

Many types of rivets are used in the sheet metal shop. The most common types are the tinman's rivets, flathead, snap head (also called roundhead) and pop rivets.

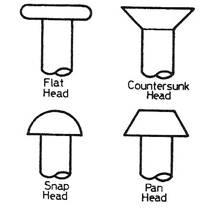

The countersunk is used where a flush surface is desired, and the snaphead when exceptional strength is required.

Figure 3 - Types of Rivets

The size of the tinman's rivets are determined by the weight of 1,000 rivets i.e. 1 lb. rivets weigh 1 lb. per thousand, 2 lb. rivets weigh 2 lb. per thousand.

Flathead rivets vary in diameter from 3/32" to 7/16" in steps of 1/32". Other rivets vary in size with 1/8" and 3/16" snaphead rivets being the most popular in the sheet metal shop.

F1athead, snaphead and countersunk rivets may be purchased in various lengths depending upon the thickness of the metal being joined.

There are no definite rules to follow in selecting the size of a rivet. In general the length should be sufficient to protrude through the pieces being joined, from l½ times the diameter of the rivet. This allows ample material for forming the head.

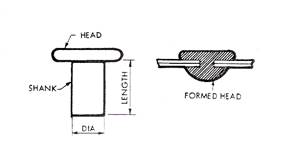

Figure 4 - Rivet Sizes

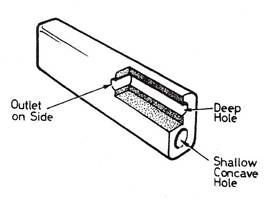

The shallow cup-shaped hole shown by the cross section view of a rivet set is used to form the head on the rivet. The deep hole is used to draw the sheets and rivet together and also to draw the rivet directly through thin sheeting without previously punching a hole. The outlet on the side allows the metal slugs to drop out. The rivet set selected should have a hole, slightly larger than the diameter of the rivet. A good job of riveting can be done with not more than six normal blows of the hammer and after a little practice this number can be cut by half.

A skilled sheet metal worker will perform the operation in sequence by striking a blow on the rivet set, one blow to flatten the rivet down and another blow on the rivet set to form the head.

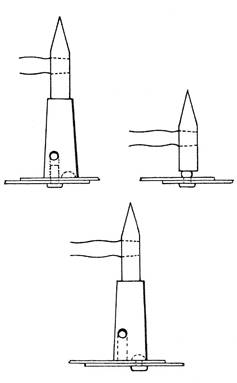

Figure 5 - Cross Section of Rivet Head

Figure 6 - Forming Rivet Heads

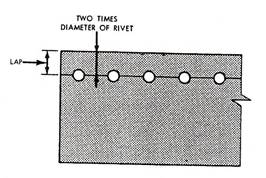

Rivet holes should be spaced according to the job specification. The space from the edge of the metal to the centre of the rivet line should be at least twice the diameter of the rivet, thus preventing the rivet from tearing out. The minimum distance between the rivets should be three times rivet dia. approx. The maximum distance between rivets should never be such that the material is allowed to buckle between them.

Figure 7 - Spacing Rivet Holes

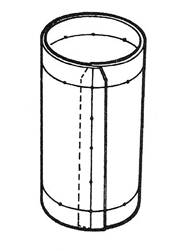

The method of spacing rivet holes for longitudinal seams in pipes is different from the manner in which the rivet holes are spaced for cross seams.

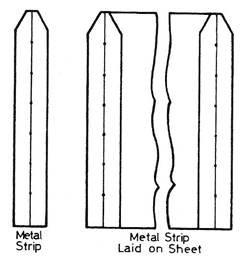

Although there are various methods of laying out holes for longitudinal seams, the metal strip procedure is generally preferred when the same job is laid out repeatedly.

This method consists of using a narrow strip of metal in which the required number of holes have being evenly spaced and pricked punched. The strip is then laid on the edge of the metal and the location of the holes marked by prick punching through the strip into the metal. One draw back to this method is, as the strip is continually used the holes become enlarged and accurate marking becomes difficult.

Care should be taken to see that the strip is not reversed when switching to the opposite side of the work, since the distances from the end holes are not alike.

Figure 8 - Longitudinal Seams

When making round pipe with riveted seams, the section of the pipe should be formed with the burred edge of the hole on the outside of the pipe. After selecting the correct size rivets and rivet set and hammer, place a rivet in one end hole and place the job on a stake. Rivet as described previously, proceed to rivet other end and centre of cylinder and then rivet alternately right and left of centre.

Figure 9 - Riveting Seams

Term |

Abbreviation |

Across Flats |

A/F |

British Standard |

BS |

Centres |

CRS |

Centre line |

CL or |

Chamfered |

CHAM |

Cheese Head |

CH HD |

Countersunk |

CSK |

Countersunk head |

CSK HD |

Counterbore |

C’BORE |

Diameter (in a note) |

DIA |

Diameter (preceding a dimension) |

Ø |

Drawing |

DRG |

Figure |

FIG |

Hexagon |

HEX |

Hexagon head |

HEX HD |

Material |

MATL |

Number |

NO |

Pitch circle diameter |

PCD |

Radius (in a note) |

RAD |

Radius (preceding a dimension) |

R |

Screwed |

SCR |

Specification |

SPEC |

Spherical diameter or radius |

SPHERE Ø or R |

Spotface |

S’FACE |

Standard |

STD |

Undercut |

U’CUT |

Table 1 - Abbreviations for Written Statements

To make a riveted butt joint it is necessary to use a separate piece of metal called a 'strap' to join the two component edges.

When two cover plates are riveted on either side of a butt joint, the joint is known as a 'double-strap butt joint'.

When single or double straps are used for riveted butt joints the rivets may be arranged as follows:

Single riveted: One row of rivets on each side of the butt;

Double, triple or quadruple riveted: In which case the chain or zig-zag formation may be employed.

Riveting is a method of making permanent joints. The process consists of drilling or punching the plates to be riveled, inserting the rivet, and then closing it by an applied compression force so that it completely fills the hole and forms a rigid joint.

A variety of riveted joints is used in construction and fabrication work:

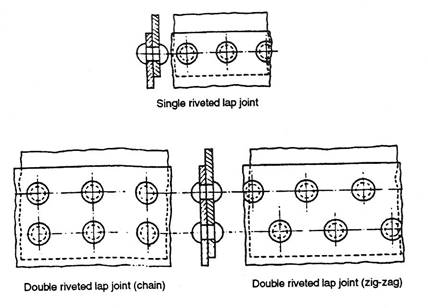

Figure 10 - Types of Riveted Joints

This is the simplest of all riveted joints and is widely used for joining both thick and thin plates. The plates to be joined are overlapped by a short distance. Then a single row of rivets, conveniently spaced along the middle of the lap, completes the joint.

A lap joint with two rows of rivets is known as a double riveted lap joint. Sufficient overlap must be provided to take a double row of rivets. This type of joint may have the two rows of rivets arranged in a square formation. This is known as chain riveting. If the rivets are arranged diagonally to form triangles, this is called zig-zag riveting.

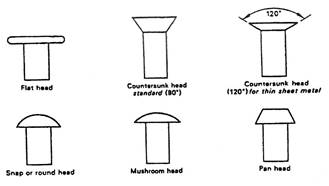

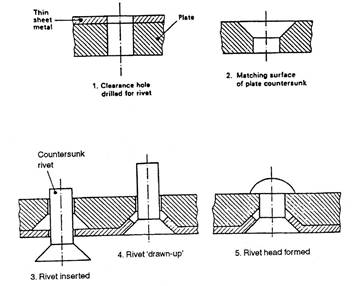

The standard types of rivet heads are shown in Figure 11 and Figure 12. Also shown is the way in which thin material is joined to thick material with countersunk rivets.

Tinners and flat-head rivets are used in most general sheet metal fabrications, where the metal is very thin and little strength is required. The countersunk head is used when a flush surface is required, and the roundhead or snaphead is most widely used where the joint must be as strong as possible. Mushroom head or 'knobbled' rivets, as they are called in the steel construction industry, are used where it is important that the rivet head does not stick up above the surface too much. They are used on outer fuselage skins of aircraft in order to decrease 'drag'. In the case of steel chutes and bunkers they are used to reduce obstruction on the inside surfaces.

Pan head rivets are very strong and are widely used for girders and heavy constructional engineering.

'Tinners' are similar to flat-head rivets. They are made of soft iron and are usually coated with tin to prevent corrosion and to make them easier to soft solder.

Always use the correct rivet for a particular metal to be riveted. When riveting aluminium, for example, use aluminium rivets; and when riveting copper use copper rivets.

Figure 11 - Standard Types of Rivet Heads

Figure 12 - Countersunk Riveting of Thin Material to Thick Material

When making joints with rivets, the following points should be followed to prevent many common defects:

Some of the common forms of defects associated with riveted connections are shown in Table 2.

Cause of Riveting Defect |

Resultant Effect |

Sheets not closed together – rivet not drawn up sufficiently. |

Weak joint. Rivet shank swells between the plates. |

Rivet holes not matched. |

Weak misshapen head. |

Insufficient hole clearance. |

|

Hole too large for rivet. |

|

Rivet set or dolly not struck square. |

|

Drilling burrs not removed. |

Not enough shank protruding to form the correct size head. |

Rivet too short. |

|

Rivet too long. |

Too much shank protruding to form required head. |

Table 2 - Common Defects in Riveting

A riveted joint is only as strong as its weakest part, and it must be borne in mind that it may fail in one of four ways:

These four undesirable effects are shown in Figure 13 to Figure 16.

Note: For design purposes the rivet should only be loaded in shear and its tensile strength in assuming to be zero.

Cause: Diameter of rivet too small compared with thickness of plate. The diameter of the rivet must be greater than the thickness of the plate in which it is to be inserted.

Prevention: Select the correct diameter rivet for the thickness of the plate.

Cause: Diameter of rivet too large compared with thickness of plate. The rivets when driven tend to bulge and crush the metal in front of them.

Prevention: Select the correct diameter rivet for the thickness of the metal plate.

Cause: Rivet holes punched or drilled too near edge of plate. Metal is likely to fail by splitting in front of the rivets.

Prevention: Drill or punch the rivet holes at the correct edge distance and use the correct lap allowance for the diameter of rivet selected.

Cause: Plates weakened by rivet holes being too close together. Plates tend to rupture along the centre line of the rivets

Prevention: Punch or drill rivet holes at the correct spacing or 'patch'. In addition remove all burrs from the holes before final assembly.

mm |

Metal Thickness S.W.X. |

Diameter of rivet (mm) |

0.80 U |

22 |

1.587 |

1.00 U |

20 |

2.381 |

1.25 U |

18 |

3.175 |

1.60 U |

16 |

3.969 |

2.50 U |

14 |

4.763 |

2.80 U |

12 |

4.763 or 6.350 |

3.55 U |

10 |

6.350 or 7.938 |

4.76 |

|

9.525 |

6.35 |

|

11.113 or 12.700 |

7.94 |

|

12.700 or 15.875 |

9.53 |

|

15.875 or 19.050 |

Code letter U denotes I.S.O. metric preferred series. |

||

Table 3 - Rivet Sizes

The length of 'shank' required to form the 'head' of the rivet (i.e. the length standing proud of the sheet surface when the rivet is inserted in the hole and held up tight) depends upon the form of the head and the 'clearance' between the rivet and the rivet hole. For ROUNDHEAD or SNAPHEAD forms the length of shank required is 1½ to 1¾ times the diameter of the rivet, the Total Length of shank required is this length plus the total thickness of the plates through which it is inserted.

The total length of shank required is equal to the total thickness of the metal to be joined plus the allowance for making the head, i.e. L = T + T + 1·5D

D = Diameter of rivet

T = Thickness of metal

L = Length of shank

Example: What length of 4 mm diameter rivet is required to form a snaphead and join two pieces of 1·6 mm sheet metal together?

Solution: L = T + T + 1·5D

= 1·6 + 1·6 + 1·5 x 4 mm

Rivet length = 3·2 + 6 mm = 9·2 mm

For the Countersunk Head form, the length of shank required is equal to the diameter of the rivet.

The total length of shank required is equal to the total thickness of the metal to be joined plus the allowance for making the head, i.e. L = T + T + D.

Example: What length of 9·5 mm diameter rivet is required to form a countersunk head and join two pieces of 4·76 mm plate?

Solution: L = T + T + D

= 4·76 + 4·76 + 9·5 mm

= 19·02 mm

Rivet length = 19 mm

Hole clearance is very important and should be kept to the absolute minimum. Table 4 shows the recommended hole clearances for various diameters of rivet.

Rivet Diameter (mm) |

Hole Diameter (mm) |

1.59 |

1.63 |

2.38 |

2.43 |

3.18 |

3.25 |

3.97 |

4.03 |

4.76 |

4.85 |

5.56 |

5.61 |

6.35 |

5.52 |

7.94 |

8.02 |

9.53 |

9.80 |

11.11 |

11.40 |

12.70 |

13.10 |

Table 4 - Recommended Hole Clearances for Various Diameters of Rivet

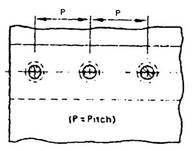

Rivet holes should be spaced according to the specification of the job. The space or distance from the edge of the metal to the centre of any rivet should be at least twice the diameter of the rivet to prevent the rivets from tearing out.

A useful rule is to make the edge distance equal to 1½ diameters plus 9·5 mm. The maximum distance from the edge is governed by the necessity of preventing the sheets from 'gaping' and should be limited to 10 times the thickness of the sheet metal or plate.

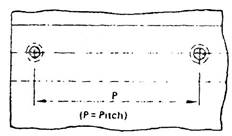

The minimum distance between rivets (known as the 'pitch') should be sufficient to allow the rivets to be driven without interference or about three times the rivet diameter.

The maximum distance between rivets should never be such that the material is allowed to buckle between the rivets and in practice should never exceed 24 times the thickness of the sheet.

Edge distance = Twice the diameter of rivet

Minimum lap = Four times diameter of rivet

![]()

Gaping

The maximum edge distance is governed by the necessity of preventing the sheets from gaping and should be limited to 10 times the thickness of the sheet or plate.

P = 3D (minimum)

D = Diameter of rivet

![]()

Bucking

Caused by too great a pitch.

P = 24T (maximum)

T = Thickness of metal

Pop rivets, unlike solid rivets, are tubular and are much lighter in weight. They are manufactured from either aluminium alloy for lightness or nickel for additional strength and corrosion resistance. They were originally designed for one-sided riveting, by which rivets can be set in places otherwise inaccessible. One operator is needed, the rivets being set or clinched with the aid of special hand-held 'lazy tongs' or pliers. Although their main application has been in aircraft construction and motor vehicle body building, where it is necessary to join thin material to thicker supporting members and lightness is important, they are often used in place of solid rivets for general riveting. They are available in diameters 2·4 mm, 3·2 mm, 4 mm and 4·8 m for joining thicknesses up to 12·7 mm.

A skilled operator may achieve speeds of 20 rivets per minute.

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/sheetmetal_notes/Riveting_M1_U12.doc

Web site to visit: http://local.ecollege.ie

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes