Use and maintenance of refinishing equipment, spray guns, cups, compressors, regulators, hoses, spray booths, respirators is of the utmost importance, for to create a perfect finish definitely requires a solid knowledge of surface preparation.

But even an extensive knowledge of surface preparation techniques and paint chemistry is not enough to assure a professional finish. It must still be applied by a spray gun and all of the variables of its use must be controlled. The equipment necessary to apply the finish; the spray gun, cup, regulator, hoses, compressor, etc. must all be matched to the job and to each other. The equipment must be used and maintained properly, with an appreciation of how it works and why is works the way it does.

The moment of truth for any finish is when the trigger is pulled on the gun.

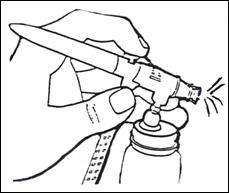

Important: To ensure that this equipment reached you in first class condition, protective coatings have been used.Flush the equipment through with a suitable solvent before use.

Air Flow Valve

If the airflow valve is fitted this can be used to reduce the inlet pressure through the gun. Screw the Adjusting Knob in to pressure.

1.2 Preventative Maintenance

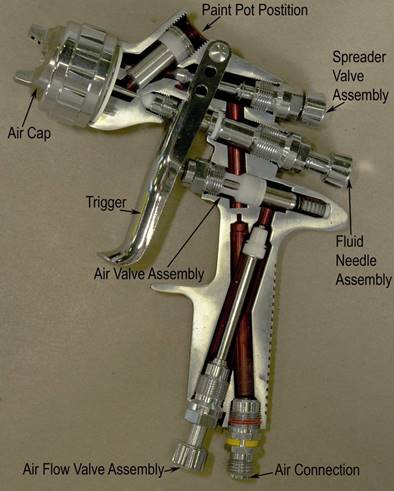

2.0 Air Atomizing Spray Gun

A spray gun is a tool which uses compressed air to atomize paint or other sprayable material and apply it to a surface. Air and the material enter the gun through separate passages and are mixed at the air cap in a controlled pattern.

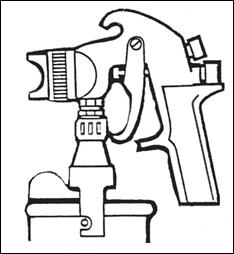

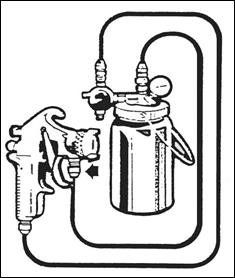

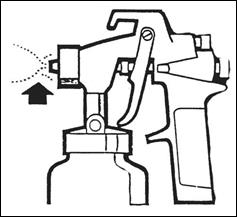

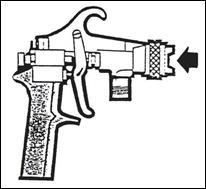

Spray guns can be classified in various ways. One is by the location of the container. Figure 2 shows a gun with an attached cup. Figure 3 illustrates a gun using material from a container some distance away. The type of material feed system can also be a way of classifying guns, with the material either kept under pressure – a pressure feed gun (figure 3) or using the suction feed principle to deliver the material to the gun (figure 2).

Figure 2 : Suction Feed Gun with Attached Cup

Figure 3: Pressure Feed Gun with Remote 2 gal. Cup

A spray gun design in which a stream of compressed air creates a vacuum at the air cap, providing a siphoning action. Atmospheric pressure on the material in the suction cup forces the material to the air cap of the gun. The vent holes in the cup lid must be open. This type gun is usually limited to quart-size or smaller containers. It is easily identified by the fluid tip extending slightly beyond the face of the air cap. Suction feed guns are suited to many colour changes and small amounts of material, such as in auto refinishing.

Pressure Feed Gun

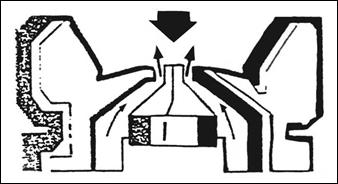

In the design of the pressure feed gun the fluid tip is flush with the face of the air cap (figure 4) and no vacuum is created. The fluid is forced to the air cap by pressure kept on the material in the system: a separate cup, tank or pump. This system is normally used when large amounts of material are too heavy to be siphoned from a container, or when fast application is required. Production spraying in a manufacturing plant would be a typical use of a pressure feed system.

In the design of the pressure feed gun the fluid tip is flush with the face of the air cap (figure 4) and no vacuum is created. The fluid is forced to the air cap by pressure kept on the material in the system: a separate cup, tank or pump. This system is normally used when large amounts of material are too heavy to be siphoned from a container, or when fast application is required. Production spraying in a manufacturing plant would be a typical use of a pressure feed system.

Figure 4 : Pressure Feed Air Cap

Bleeder Type Gun

A bleeder type gun is designed without an air valve. Air passes through the gun at all times. It is usually used with small compressors of limited capacity and pressure which have no pressure-controlled device such as an unloader or pressure switch. In this type of gun (figure 5) the trigger only controls the flow of fluid.

A bleeder type gun is designed without an air valve. Air passes through the gun at all times. It is usually used with small compressors of limited capacity and pressure which have no pressure-controlled device such as an unloader or pressure switch. In this type of gun (figure 5) the trigger only controls the flow of fluid.

Figure 5 : Bleeder Type Gun

Non-Bleeder Type Gun

A non-bleeder type gun is equipped with an air valve to shut off the flow of air when the trigger is released: the trigger controls both air and fluid flow. It is used with compressors having some type of pressure control device.

A non-bleeder type gun is equipped with an air valve to shut off the flow of air when the trigger is released: the trigger controls both air and fluid flow. It is used with compressors having some type of pressure control device.

Figure 6 : Non-Bleeder Type Gun

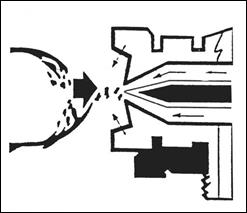

External Mix Gun

This type, as shown in figure 7 mixes and atomizes air and fluid outside the air cap. It can be used for applying virtually all types of materials and is desirable for spraying fast drying paints such as lacquer. It is also used when a high quality finish is desired.

This type, as shown in figure 7 mixes and atomizes air and fluid outside the air cap. It can be used for applying virtually all types of materials and is desirable for spraying fast drying paints such as lacquer. It is also used when a high quality finish is desired.

Figure 7 : External Mix Gun

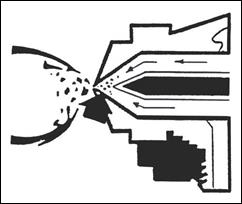

Internal Mix Gun

This gun type mixes air and material inside the air cap before expelling them, as shown in figure 8. it is usually used where low air pressures and air volumes are employed or where slow drying materials are being sprayed. A typical example would be spraying flat wall paint or outside house paint with a 1/4 or 1/3 HP compressor. Internal mix guns are rarely used for refinishing when very fast drying materials are being sprayed.

This gun type mixes air and material inside the air cap before expelling them, as shown in figure 8. it is usually used where low air pressures and air volumes are employed or where slow drying materials are being sprayed. A typical example would be spraying flat wall paint or outside house paint with a 1/4 or 1/3 HP compressor. Internal mix guns are rarely used for refinishing when very fast drying materials are being sprayed.

Figure 8 : Internal Mix Gun

Airbrush

This is a very small, lightweight spray gun used for painting very fine detail such as stripes. It has a paint capacity of ½ to 1 ounce and the spray pattern is adjustable up to about the size of a 5c piece.

This is a very small, lightweight spray gun used for painting very fine detail such as stripes. It has a paint capacity of ½ to 1 ounce and the spray pattern is adjustable up to about the size of a 5c piece.

Figure 9 : Airbrush

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/vbr_notes/module5/m5u2.doc

Web site to visit: http://local.ecollege.ie

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes