Tools used in the working of sheet steel

One of the characteristics of the skilled worker is the way in which he selects and uses his tools. For this reason, it is essential that you know how to select and use both hand and machine tools correctly. If you do this you will save time and the work will be much easier. When you have selected the correct tool for the correct operation you have taken the first step in becoming a successful craftsman.

1.1 Recognition, Selection and Maintenance of Hand Tools

Hand Tools:

Sheetmetal hand tools are used to scribe or measure lines, perform layout operations and shape or cut metals. Some of the hand tools in the following notes actually perform these operations while others such as stakes and punches serve as aids in performing them. It is important to keep tools in good condition, prevent tools going rusty by giving steel tools an occasional oiling. Tools with sharp points should be stored carefully.

Figure 1: Scriber

It is used to mark lines on metal. It can be used in conjunction with a straight edge and square.

Figure 2: Straight Edge

Figure 2: Straight Edge

The straight edge is used as a guide for a scriber or pencil when marking a straight line or drawing a line between two points. It is also used in conjunction with a square to draw lines at right angles.

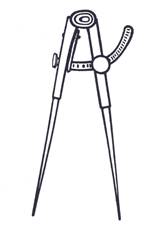

Figure 3: Dividers

Figure 3: Dividers

Made with each straight leg tapered to a needle point. Dividers are manufactured in various sizes and types and are used to space off equal distances, to divide lines into equal parts and to scribe arcs and circles. The spring loaded screw type are the more accurate type.

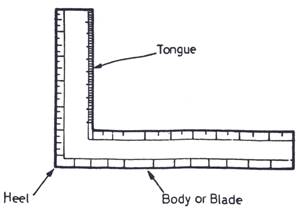

Figure 4: Steel Square

The flat steel square is used to layout right angles (90º) and can also be used as a scale. It is an invaluable tool for accurate layout work in pattern drafting. The long arm is known as the body or blade, the short arm is known as the heel or tongue. These squares come in various sizes.

The flat steel square is used to layout right angles (90º) and can also be used as a scale. It is an invaluable tool for accurate layout work in pattern drafting. The long arm is known as the body or blade, the short arm is known as the heel or tongue. These squares come in various sizes.

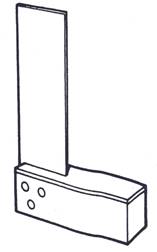

Figure 5: Steel Try Square

It is used for making and checking right angles (90º). These squares come in various sizes.

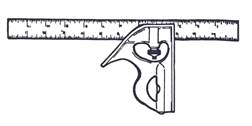

Figure 6: Combination Square

Is one of the most useful and convenient tools for laying out small work. It is used as a square for measuring or laying out 90º and 45º angles. A spirit level is mounted in the stock.

Is one of the most useful and convenient tools for laying out small work. It is used as a square for measuring or laying out 90º and 45º angles. A spirit level is mounted in the stock.

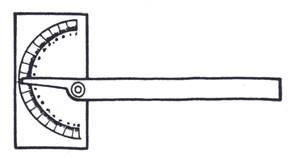

Figure 7: Swinging Blade Protractor

It is a device for measuring and laying out angles from the edge of the work. This protractor consists of a head and a movable blade. The head of the protractor has a semicircular scale graduated from zero to 180º.

It is a device for measuring and laying out angles from the edge of the work. This protractor consists of a head and a movable blade. The head of the protractor has a semicircular scale graduated from zero to 180º.

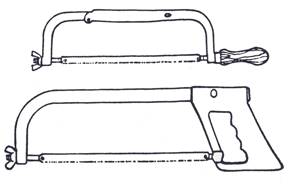

Figure 8: Hack Saw

Figure 8: Hack Saw

The hack saw is used for cutting materials by hand. It consists of a renewable hardened steel saw blade fitted into an adjustable frame, which is usually provided with a screw adjustment for controlling the tension of the blade. It is necessary to have both junior and senior hacksaws in your tool kit.

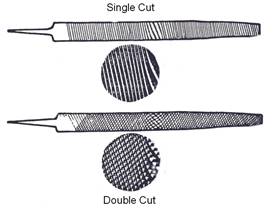

Figure 9: Files

There are many shapes and sizes of files available with various grades of cut. Files are used to remove burrs from sheets of metal, to straighten uneven edges and for various other operations that require a small amount of metal to be removed. They should always be used with a handle. Common types used by the sheet metal worker are: flat, square, round and half-round.

There are many shapes and sizes of files available with various grades of cut. Files are used to remove burrs from sheets of metal, to straighten uneven edges and for various other operations that require a small amount of metal to be removed. They should always be used with a handle. Common types used by the sheet metal worker are: flat, square, round and half-round.

The offset combination of universal snips is preferred by the panel beater when cutting thin gauge metal. Universal snips are suitable for cutting straight lines, outside and inside curves. A right and left hand pair of combination snips will be suitable for most of the sheet metal cutting that will be encountered by the panel beater and there is no need for any curved blade snips. When the more popular right handed snips are used the waste metal forms a coil to the left of the cutting blades, thus causing little distortion to the surface of the sheet or panel being cut. Similarly, with the left handed pair of snips the waste metal passes to the right of the cutting blades, leaving the distorted sheet or panel on the left. Snips can be obtained in varying sizes with either straight or crank handles. A straight pair of snips is often necessary for long straight cuts.

Hammers

The planishing or panel hammer is used more than any other tool in the body repair trade and for this reason the best hammer available should be obtained. The principal purpose of the panel hammer is for the smoothing and finalising of a panel surface after it has been roughed out to the required shape. The planishing hammer should have a true and unmarked face, and it must be kept polished and free from grit.

Hand Dollies

These are cast or drop forged steel blocks, heat treated to provide the correct degree of hardness. The shapes of the dolly blocks have been designed to provide a working surface that is highly polished and suitable for use on the many contours found on motor vehicle bodies.

They are used in conjunction with the planishing hammer or beating file and acts as a support or anvil to smooth out the surface area of panels that have been damaged. These dollies, together with the planishing hammers, are the most essential tools for the panel beating trade. Obviously one dolly block will not be suitable for all shapes requiring planishing; therefore it is advisable to have a set of these dollies which would be suitable for a wide range of shapes and contours encountered on the ever-changing body styles of the modern motor vehicle. Dollies should have a true and unmarked face and must be kept polished and free from grit.

Body Spoons

These tools are made from a high-grade steel which has been drop forged and heat treated. They are sometimes called prying spoons because the spoon end is used in the same manner as a dolly in conjunction with a hammer. The body spoon really does the same job as a dolly block but is designed for use in confined spaces where a normal dolly block cannot be held in the hand, e.g. between door frames and outer door panels. The spoon end, which acts as the dolly, must be kept in good condition and free from grit.

File Hammer

This tool is designed to be used like a hammer, in conjunction with a dolly block, although it is actually a file with a serrated face and is suitably shaped for holding in the hand. The milling on the file blade tends to shrink the panel as well as leaving a regular rough patterned surface ideal for locating low spots on the panel under repair and for finishing with a body file. The tool is used in conjunction with a hand dolly and with a glancing blow. It is most effective on flat sections, where it will be found ideal for smoothing and levelling out wavy panels. Two types of beating files are available; one is flat for low and high crowned surfaces, while the other is half-round in shape and is used on convex or reverse-curved panel sections.

Mallets

Mallets can be of the round or pear-shaped type made from boxwood or lignum vitae, or can be rubber, aluminium or plastic faced. Some mallets have interchangeable heads so that the correct head can be used for the material being worked on. A mallet is greatly used in the initial stages of smoothing and roughing out of a panel prior to planishing.

Body Files

Flexible panel file

This tool is designed with a two-position handle, and has a 14in (30cm) spring position handle, and has a 14in (30cm) spring steel backing plate to give adequate support over the whole blade. Positioned between the two hand grips is a turn-screw threaded left and right hand for adjusting the blade to concave or convex positions to suit the user’s requirements. The main use of this stool is to assist in the final planishing of the work. First and most important, it locates areas which are low on the surface of the panel under repair: second, it files out small marks or defects on the panel surface. It can be adapted to file the surface of almost any shaped panel by setting the blade either, straight, concave or convex. The file blades are specially designed so that they do not remove too much metal which has been painted, soldered or plastic filled. It is important to release the tension of the file blade after use.

Punches

Hole punches: Have interchangeable heads to punch holes of either ![]() in (5mm) diameter hole is for gas welding or brazing and the ¼ in (6mm) holes is for MIG welding.

in (5mm) diameter hole is for gas welding or brazing and the ¼ in (6mm) holes is for MIG welding.

Wing punch: Is a hole punch with a specially designed head which allows it to be used on wing panels and channel sections and also fit over roof gutters and wheel arches

Edge setters: The edge setter is a portable, hand-operated tool designed to provide a ‘joggled’ joint or stepped edge on a repaired or new panel, thus creating a flush fitting lap joint.

2.0 The Function of Sheet Metal Equipment

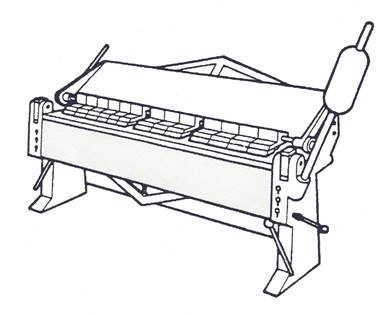

Box and Pan Folders

The most important points when using this machine is:

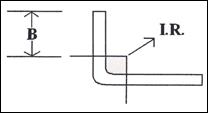

The main specification of a folding machine is:

B refers to the smallest width which will clamp securely in the machine. If B is smaller than 8 to 10 times metal thickness it may slip out.

B refers to the smallest width which will clamp securely in the machine. If B is smaller than 8 to 10 times metal thickness it may slip out.

The three main steps in folding work are:

Clamping

In clamping, the amount of lift of the clamping beam is important. It should be sufficient to allow the fitting and use of special clamping blades, or to give adequate clearance for previous folds.

Folding

Care must be taken to see that the folding beam will clear the work, particularly when making second or third folds. Some folding machines are designed to fold radii above the minimum, either by fitting of a radius bar or by adjustment of the folding beam.

Removal of the work

Care must be taken in folding to ensure that the work may be easily removed on completion of the final bend. The sequence of folding must be carefully studied. The lift of the clamping beam is important here. Some folding machines known as universal folders have a swing beam. The work may be completely folded around this beam, which is then swung out to allow removal of the work.

2.1 Hazards Created by Sheet Metal and Sheet Metal Equipment

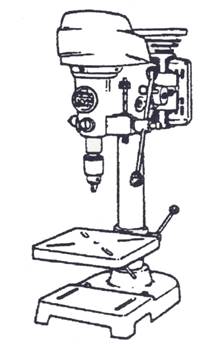

Radial Drill

There are floor mounted and bench mounted types. Each type should be securely bolted down.

Figure 11: Radial Drill

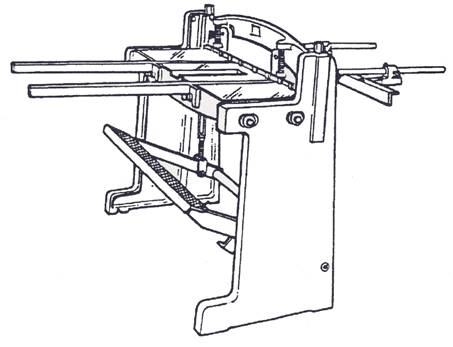

Treadle Guillotine

Only one sheet should be cut at a given time

Only one sheet should be cut at a given time

Figure 12: Treadle Guillotine

When working with the bending machines the existing safety rules must be kept to avoid personal or material injury.

Always wear the appropriate protection at all times i.e.

Good housekeeping is an important element in accident prevention. Good housekeeping begins with planning ahead. Materials should be neatly stacked and any spillages of oil or grease should be cleaned up immediately. Each person should pay attention to his own work area. A neat work area reflects a worker’s approach to his work and equipment. The apprentice should always think safety. There are too many hazards in the work area to list. The apprentice should cultivate a positive attitude towards safe working habits.

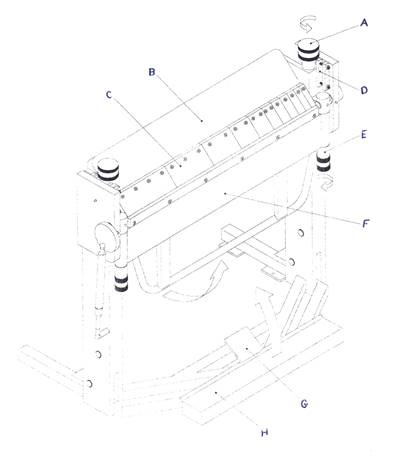

Box and Pan Bending Machine

This type of machine, while suitable for all types of bending operations, has special provision for folding pans, trays or boxes. No rods, wires or metal beyond the capacity of the machine should be bent on this machine.

Always adjust for metal thickness.

Figure 14: Box and Pan Bending Machine

Operation

When bending the lock for the upper beam (B) is released by using the pedal (G). Now the sheet can be entered. The upper bean is pressed down again by using the pedal (H). Before the lock (G) for the upper beam is activated it is necessary to adjust the handles (A) so it is possible to press the pedal home. Finally the handle (E) for the bending beam (F) is adjusted, so the bending crack (see fig 16) correspond with the sheet dimension. It might be necessary to dismount one or more of the segments (C) in the upper beam in order to make the best possible use of the many possibilities.

Figure 15: Metal Forming Equipment

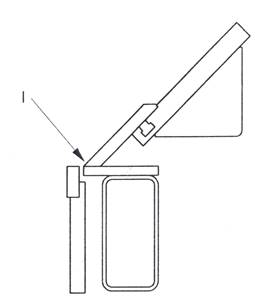

Figure 16: Bending Crack

When working with the bending machines the existing safety rules must be kept to avoid personal or material injury.

It is not recommended to bend sheets which exceed the maximum sheet dimension (see technical specifications).

2.2 Basic Maintenance of Sheet Metal Forming Machinery

To secure unnecessary wear and tear the four nipples must be lubricated regularly. It is advised not to change the adjustment of the upper beam in the slide rails (D) see figure 15, as this is correctly adjusted from the factory.

If these directions and maintenance instructions are kept it is only necessary to adjust the position of the slide rails due to wear and tear and if the segments are grinded off.

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/vbr_notes/m1u6.doc

Web site to visit: http://local.ecollege.ie/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes