Gas welding

Gas welding

Lecture: Khalid Al-Janabi

GAS WELDING

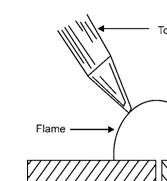

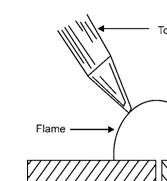

Gas welding is the process in which a gas flame is used to raise the temperature of the metals to be joined. The metals are heated up to melting. The metal flows and on cooling it solidifies. A filler metal may be added to the flowing molten metal to fill up cavity made during the end preparation.

Fig.1: Gas Welding

Many combinations of gases are used in gas welding. But the most common of these is oxygen and acetylene.

Oxy-acetylene Welding

The process of oxy-acetylene welding can be used for almost all metals and alloys for engineering purposes. A high temperature flame (3200°C) can be produced by this method. There are two systems of oxygen-acetylene welding.

- High Pressure System: In this process the oxygen and acetylene are taken for use from high pressure cylinders.

- Low Pressure System: In this system oxygen is taken from high pressure cylinder and the acetylene is produced by the action of Calcium carbide and water.

CaC2 + 2H2O = Ca (OH)2 + C2H2

Apparatus for Gas Welding

Principle of Oxy-acetylene Welding

A very hot flame is produced by burning of the gases coming through the torch tip. The edges to be welded are heated up to melting. A filler metal is also added to complete the welding. This molten metal mixture when solidifies on cooling forms a welded joint.

Oxygen cylinder and acetylene cylinder are filled with gases. Both the cylinders are attached with pressure gauges, regulators and cylinder valves. The cylinder containing oxygen is painted black whereas the acetylene cylinder is painted maroon. Hose pipes, are provided with each cylinder. These pipes are connected to welding torch.

Welding Process

To start welding, the acetylene control valve is turned first. When acetylene comes out of the nozzle, it should be ignited with spark lighter. It will give a yellow-colored smoke flame. After it, oxygen cylinder valve is opened and supply is increased until a most suitable flame is obtained. Then the flame is focused on the edges to be welded. Flux and filler metal are also added with the heat of flame. The edges and filler metal melt and a joint are formed after cooling of the molten metal. The joint may be formed with or without using filler metal.

Applications

Oxy-acetylene welding is particularly used for sheet metal work. All the metals can be welded with proper filler metals. Same equipment may be used for cutting purposes.

Advantages of Oxy-acetylene Welding

The main advantages of oxy-acetylene welding are given below:

- Equipment is cheap as compared to other welding process.

- It can be used for welding of all types of metals.

- Maintenance of equipment is very less.

- It is a portable process.

- It can be used for cutting of metals of small thickness.

- It is specially used for sheet metal work.

Disadvantages

- It takes long time for heating the job as compared to the arc welding.

- The heat affected area is more.

- This is prone to corrosion and brittleness.

- Gases are expensive and difficult to store.

2.Types of Gas Flames

There are three types of gas flames:

Oxidizing Flame 2. Carburising Flame 3.Neutral Flame

- Oxidizing Flame: When the volume of oxygen gas is more than the volume of acetylene mixed into the torch. This flame is used for welding brass and is also used for cutting the metals.

- Carburising Flame: When the volume of acetylene mixed is more than oxygen, carburising flame is formed. This flame is used for welding nickel, monel etc.

- Neutral Flame: It is known as balanced flame. Oxygen and acetylene gases are mixed in equal volumes. Neutral flame is used for normal welding of steel, cast iron etc.

Fig. 3: Types of Flames

4.Gas Welding Techniques

There are two types of gas welding techniques:

- Left ward welding

- Right ward welding

- Left Ward Welding: In this welding the tip of the torch is held at 60 to 70°C to the plates. And the filler rod is inclined at 30 to 40°C in opposite direction. In this method, the plate edges are heated immediately after the molten metal. The torch tip and filler rod are moved slowly in the direction towards left. The technique is illustrated in the Fig.4.

Fig. 4: Leftward Welding

- Right Ward Welding: In right ward welding the torch is kept at 40 to 50°C to the job to be welded. Torch is moved towards right as shown in the Fig. 5. Right ward welding is done for heavy sections only.

Fig. 5: Rightward Welding

Flux

The chemicals which deoxidize the metal surface and provide inert atmosphere around the molten metal are known as fluxes.

The main function of flux is given below:

- To prevent oxides on the hot surfaces.

- To reduce the viscosity of molten metal.

- It maintains a steady arc in case of arc welding. Fluxes are available as liquid, powder, paste and gas.

Powder flux is sprinkled on the surfaces to be welded or the filler rod is dipped into the powder. Liquid & paste fluxes are sprayed on the surfaces to be welded.

Gas fluxes are used to form inert atmosphere around the joint to be welded

Filler

The rod which provides additional metal in completing the welding is known as filler. The composition of filler metal should be the same as that of the metals to be welded.

Gas Welding Equipment

Details of Gas welding equipment are as under:

- Oxygen Cylinder: As shown in Fig 6. Cylinder is made up of steel in capacity range 2.25 to 6.3 m3. The cylinders are filled with oxygen at about 150 kg/cm2 at 21°C. A safety valve is also provided on it. The cylinder can be opened or closed by a wheel which operates a valve. A protector cap is provided on the top of a cylinder to safeguard the valve.

- Acetylene Cylinder: As shown in Fig. 7. Acetylene cylinders are also made up of steel. Gas is filled at a pressure of 18-20 kg/cm2. The capacity of the cylinder is about 10m3. Regulator valve and safety valve are mounted on cylinder. Safety plugs are also provided on the bottom of the cylinder. When filled into the cylinder, the acetylene is dissolved in acetone.

- Regulator: Regulator is used to control the flow of gases from high pressure cylinder.

A simple type of regulator is shown in the Fig. 8.

- Torch: Torch is a device used to mix acetylene and oxygen in the correct proportion and the mixture flows to the tip of the torch. Refer Fig. 9. There are two types of torches:

- Low pressure or injector torches

- Medium pressure or equal pressure torches

- Low Pressure or Injector Torch: These torches are designed to use acetylene at low pressure. The pressure is kept very low up to 0.7 kg/cm2. But the oxygen pressure is very high.

- Medium Pressure or Equal Pressure Torch: In this type of torch the acetylene is taken at a pressure equal to 1 kg/cm2, the oxygen is always supplied at high pressure. Both types of torches are provided with two needle valves. One regulates the flow of oxygen and the second valve controls the flow of acetylene. A mixing chamber is provided to mix the gases.

- Torch Tips: For different types of jobs, different tips are used. The size of the tip is specified by the outlet hole diameter. More than one hole is also provided in tips. The tip is screwed or fitted on the front end of the torch. Various types of tips are shown in the Fig.10.

Fig. 10: Torch Tips

- Goggles: Gas flames produce high intensity light & heat rays, which are harmful to naked eye. To protect the eyes from these rays, goggles are used. Goggles also protect the eyes from flying sparks.

Fig. 11: Goggles

- Lighter: For starting the flame, the spark should be given by a lighter. Match sticks should not be used, as there is risk of burning hand.

- Fire Extinguishers: Fire extinguishers are used to prevent the fire that may break out by chance. Sand filled buckets and closed cylinders are kept ready to meet such accidents.

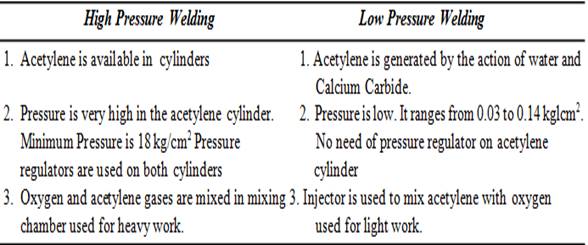

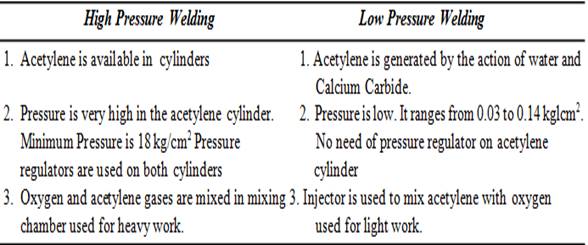

Difference between High Pressure and Low Pressure Gas Welding

Safety Precautions in Gas Welding

The following safety precautions must be observed while working in welding shop:

- Always handle the gas cylinders with care.

- The adjusting screw on the regulator must be fully released before opening a cylinder valve.

- Never use matchsticks for lighting a torch.

- Never lubricate the regulator valve with oil or grease, it may cause explosion.

- Always use goggles while working.

- Proper ventilation must be provided in the shop.

- Acetylene cylinders should be stored in up right position.

- Do not open acetylene cylinders near sparks or fire.

- Never remove torch tips with pliers.

- The cylinder should be leak proof.

- Always use protective caps over the valves.

- Keep in mind the location of the fire extinguishers.

Source: http://www.uobabylon.edu.iq/eprints/pubdoc_3_16705_6027.doc

Web site to visit: http://www.uobabylon.edu.iq

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly.

Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

Gas welding

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes

Gas welding

![]()

![]()

![]()

![]()

![]()

![]()