In this section you will learn about:

Paint

For hundreds of years people have been finishing the internal and external walls of their buildings with various mixtures or fabrics to decorate, preserve or waterproof them. Very early on, kalsomine (made from powdered limestone) was used to paint interior walls and varnishes and shellac were developed to preserve and decorate timber.

Lacquers, made from resins, came from China originally and became very popular in the late seventeenth and eighteenth century Europe for furniture and wall panels. In sixteenth century France painted hessian was popular as an interior wall finish, later superseded by exotic materials such as brocades. Wallpaper, as we know it, did not become really popular until the middle of the nineteenth century when printing processes made available brightly coloured and patterned wallpapers at prices many people could afford. Many coatings and coverings are now made either entirely or partially from plastics.

Today we expect a surface coating or covering to contribute to or provide any or all of the following:

Surface finishes may only represent up to 5% of the initial building cost but contribute greatly to the maintenance costs of the building. Selection of the correct system and adequate preparation of the surface is, therefore, important.

Broadly speaking, paint is a mixture of:

The binder, as the name suggests, binds the other ingredients together, forming a solid, elastic film which must adhere to the surface, sometimes penetrating and sealing it as well. A paint is classified according to the type of binder.

These are based on oils which react with the oxygen in the atmosphere to solidify. Straight oil paints based on naturally drying oils, such as linseed oil, are rarely used today and have been largely replaced by paints modified with synthetic binders called alkyds. These paints are often called enamels or alkyd enamels.

These binders comprise small globules of resin which are suspended or dispersed as an emulsion in water. As the water evaporates, the globules coalesce to form a solid film. Paints based on this type of binder are commonly known as plastic or latex paints and the resins used include PVA, acrylic, polyurethane or combinations of these. They are often referred to as emulsion paints.

These binders are dissolved in a solvent which evaporates leaving a solid film, such as lacquer and chlorinated rubber.

These are usually two-pack paints and the binder forms as the two compounds are mixed together and react chemically. Once mixed, the paint must be applied within a few hours. Epoxy (epoxide) resin paints are examples.

Pigments are used to make the paint opaque, to hide the background, and to provide the required colour. For instance, titanium dioxide is used for opacity and another compound such as iron oxide might be used to impart the colour.

Additives and extenders are included in varying quantities and have a great influence on the properties of the paint. The roles of additives and extenders tend to merge but basically they are as follows.

Additives might include fungicides and driers in oil and alkyd paints or dispersing and emulsifying agents in latex or plastic paints.

Extenders are used to achieve the required viscosity, body and surface appearance.

The medium can either be a solvent in which the binder is dissolved or a dispersing medium in which it is suspended. Examples of solvents include mineral turpentine or benzine derivatives. The dispersing medium most commonly used for plastic and latex paints is water.

Thinning and cleaning up depends on the nature of the dispersing medium. Oil-based paints require turpentine or white spirit whereas water-based paints can be thinned and cleaned up with water. Special solvents are required for other types of paints.

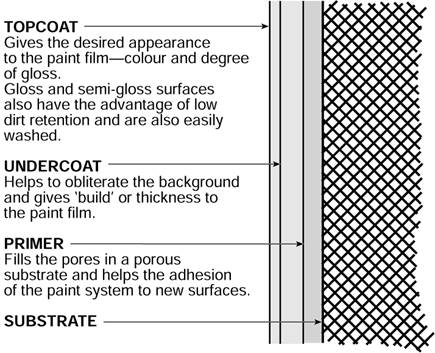

Most paint systems include the following:

The choice of system depends on the nature of the surface to be painted and the finish required (refer to Figure 1).

Figure 1: Break-up of a paint system

Each component of the system performs a particular function but in some cases, as with plastic paints, a paint can perform more than one function. The type of coat selected must be compatible with the substrate (background) and with adjacent coats.

The primer can fulfil a number of functions including:

Primers which etch the surface and inhibit corrosion are available for use on metals.

Undercoats must cover the original colour of the surface and fill in any small depressions.

Finishing coats provide the final colour and texture and offer the final protection against weather, chemical and mechanical damage. Finishing coats are available in gloss, semi-gloss or satin, flat or matt and in various textures.

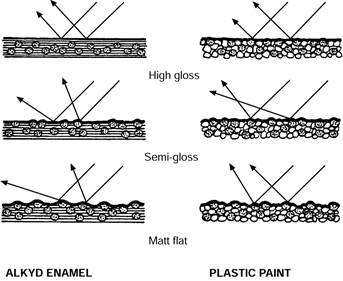

Figure 2 demonstrates how, on a microscopic level, the medium evaporates leaving various amounts of pigment exposed, thus forming the various finishes.

Figure 2: Microscopic cross sections showing how light is reflected, giving characteristic shiny or matt appearances

The substrate is the surface which is to be painted.

Alkalinity, porosity and loose particles on the surface to be painted can affect the adhesion and durability of a paint system.

Materials such as concrete, cement render, mortar and solid plaster contain small amounts of alkaline materials (mainly from the lime) and some paints, such as the alkyd enamels, are susceptible to alkali attack, which causes breakdown of the film. The gloss and semi-gloss enamels are more susceptible than the flat enamels and must be separated from the substrate by an alkali sealer.

Gloss and semi-gloss alkyd enamels are also adversely affected by porous surfaces which absorb the medium and binder unequally. The use of a suitable undercoat will prevent unequal absorption of the finishing coats. Plastic or latex paints are not affected by porous surfaces because the globules of resin are not absorbed but sit on the surface.

Loose surface material can reduce adhesion. Enamel paints tend to penetrate the loose material and bind it together but plastic or latex paints just tend to sit on the surface. For this reason, loose material should be removed with a brush or scraper before painting with a plastic or latex paint. If the surface is particularly loose, treatment with a 15% solution of phosphoric acid may be required.

In addition to consideration of the nature of the substrate, the choice of a paint system ultimately depends upon:

Table 1, on the next page, is a summary of paint systems for various substrates.

A variety of paints for special purposes are available, including the following:

|

|

As with all paint systems, it is best to seek the advice of the manufacturer for special requirements and, having selected a manufacturer, it is wise to choose your entire system from your chosen brand to avoid incompatibility between coats.

Substrate |

Location |

Finish required |

Special preparation |

Recommended paint |

|

Concrete, concrete masonry, mortar joints, fibrous cement |

Interior |

Matt |

Clean loose material |

Interior or exterior quality latex |

|

Fibrous plaster, plasterboard, calcium-silicate and clay bricks |

Interior |

Matt |

Smooth joints |

2 coats latex |

|

Hardboard, particle board, plywood |

Interior/ exterior |

Matt |

|

Alkyd undercoat, latex top coats |

|

Timber * |

Interior |

Gloss recommended |

Smooth, sand, stop and fill |

1 coat wood primer |

|

Unweathered galvanised steel # |

Exterior |

– |

Wipe surface with mineral turpentine |

1 coat calcium plumbate |

|

Small areas of mild steel |

Interior |

Gloss recommended |

Clean carefully with |

1 coat wood anti-corrosive metal primer |

|

* Latex paints are too soft for heavy wear and tear on timber.

# With galvanised steel, where possible, it is better to use pre-painted or coated roofing products.

Table 1: Recommended paint systems

On site, paint can be applied by:

– can be used to achieve metallic and graded effects

– the only suitable method for quick-drying paints (the hot spray process reduces the viscosity of a paint without the addition of a solvent)

In the factory, paint can be applied by:

One of the most common causes of breakdown of painted surfaces is inadequate preparation of the substrate. Sometimes brushing is adequate but in other cases dirt must be removed by washing and scraping, using suitable solvents for oils and stains.

Previously painted surfaces might simply require priming, filling and rubbing down.

However, where a perfect surface is required paint can be removed by burning off and scraping, using solvent and chemical removers or by steam stripping. Water-soluble paints, such as tempera, must be removed before painting as they prevent the formation of a key.

Generally speaking, it is best not to paint in wet, damp or foggy weather or below 4°C, in direct sunlight or in dusty conditions. Humid conditions delay drying of ordinary paints.

Each coat should be thoroughly dry before the next is applied.

Good ventilation is required to assist drying and sometimes to remove noxious fumes.

……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

Clear finishes are used to enhance the natural appearance of the substrate and in many cases waterproof and protect it as well. They may or may not include some colour pigment and, depending upon the type of compound, may be available in gloss, semi-gloss or matt finishes.

In general, clear finishes lack sufficient pigment to filter out damaging ultraviolet light and are therefore much less durable than paints in exposed conditions. Consequently, the choice is limited for external conditions.

Interior clear finishes have been formulated specially to suit the substrate. We will deal with them according to the nature of the substrate.

The clear finishes currently available include the following:

When choosing a clear finish for a timber surface it is important to define your requirements carefully, taking into account the nature of the timber. For instance, the clear finish chosen may actually be harder than the timber substrate and breakdown of the finish has often occurred because an impact has caused denting of the timber below, not the finish itself. The result is a loss of bond between the substrate and the finish. Thus, softer timbers should be finished with the more flexible finishes.

As with painted surfaces, a good finish can only be obtained with adequate preparation of the substrate. In general, the surface must be clean, firm and dry but additional preparation might include:

Clear finishes which will help to preserve the natural appearance of timber in exposed conditions include the following:

In general, a lower standard of preparation is required for external timber but any stopping or filling must be water-resistant and galvanised nails should be driven well below the surface and filled to avoid rust stains.

Clear finishes designed to reduce soiling and make the surface impervious to water are frequently applied to masonry surfaces, finishes based on silicone being the most effective and the most expensive alternatives.

Finishes based on acrylic resins and polyurethane two-pack systems are available to give some protection to metals such as copper. They must be applied by spraying and preferably in a factory.

Vitreous enamel (often called porcelain enamel) is actually glass which is fused under extreme heat to metal surfaces. The process is expensive but the resultant coating is extremely hard and durable and adheres firmly to the substrate so that where damage exposes the underlying surface, rust will not creep under the rest of the coating.

The finish is applied after fabrication is complete and the number of coats required depends upon the location of the finished component.

A wide range of colours is available and finishes can be gloss, semi-gloss, matt or textured. The latter collect grime easily and are not suitable for external use.

Vitreous enamel coatings are used for metal-wall infill panels, mullions, lift panels, steel rainwater components and baths.

Plastics can be applied in a number of ways to metal, timber and other surfaces and form continuous protective coatings which, in general, are more durable and tough than ordinary painted finishes.

Some are extremely durable (eg polyvinyl fluoride and nylon) but others (eg, polyethylene) deteriorate in exterior conditions, fading and becoming brittle.

Many colours are available though some are not suitable for external use and the finish obtained is usually warm to the touch, and smooth, easily cleaned and provides electrical insulation.

The coatings are applied to the components or sheet materials in the factory and are used for sheet metal, and extruded components, such as handrails, in particular.

……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

As briefly mentioned at the beginning of the unit, sheet coverings such as wallpapers and fabrics have been used to decorate wall and ceiling surfaces for hundreds of years.

Wallpapers and textiles are still the easiest way to obtain large areas of highly patterned or textured wall surfaces and in addition can contribute to acoustic modification of the space.

Light-fastness varies and few are suitable in areas receiving strong sunlight.

Sheet coverings used frequently include the following:

The wall surface should be dry and chemically neutral with a slight suction. This is achieved by removal of efflorescence by brushing and painting with an alkali-resistant primer.

If mouldy, old wallpaper should be removed and the surface treated with a fungicide. Depressions and cracks should be filled and a lining paper could be applied to improve the substrate.

Galvanising is the process of coating steel and iron with zinc to form a protective coating. The steel is lowered into a molten bath of zinc heated to approximately 5000C and emerges with a shiny coating of zinc. The zinc coating acts as a ‘sacrificial’ anode and corrodes to protect the steel. Since its rate of corrosion is slow, the steel can remain protected for hundreds of years, depending on the environment.

Zincalume

Zincalume is a newer protective coating and is a combination of zinc and aluminium (45% & 55% respectively), which is applied in a factory process to sheet steel used for roofing and cladding in the building industry.

…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

……………………………………………………………………………

……………………………………………………………………………

…………………………………………………………………………….

Source: http://bctcwagga.riverinainstitute.wikispaces.net/file/view/Unit+7+Paints+and+Coatings.doc

Web site to visit: http://bctcwagga.riverinainstitute.wikispaces.net

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes