Polymer Important Information

1. Introduction

Prior to the early 1920's, chemists doubted the existence of molecules having molecular weights greater than a few thousand. This limiting view was challenged by Hermann Staudinger, a German chemist with experience in studying natural compounds such as rubber and cellulose. In contrast to the prevailing rationalization of these substances as aggregates of small molecules, Staudinger proposed they were made up of macromolecules composed of 10,000 or more atoms. He formulated a polymeric structure for rubber, based on a repeating isoprene unit (referred to as a monomer). For his contributions to chemistry, Staudinger received the 1953 Nobel Prize. The terms polymer and monomer were derived from the Greek roots poly (many), mono (one) and meros (part).

Recognition that polymeric macromolecules make up many important natural materials was followed by the creation of synthetic analogs having a variety of properties. Indeed, applications of these materials as fibers, flexible films, adhesives, resistant paints and tough but light solids have transformed modern society. Some important examples of these substances are discussed in the following sections.

2. Writing Formulas for Polymeric Macromolecules

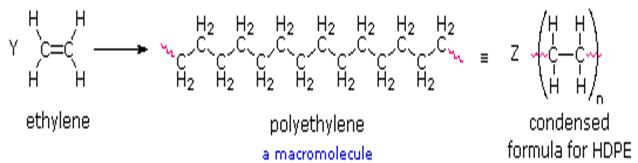

The repeating structural unit of most simple polymers not only reflects the monomer(s) from which the polymers are constructed, but also provides a concise means for drawing structures to represent these macromolecules. For polyethylene, arguably the simplest polymer, this is demonstrated by the following equation. Here ethylene (ethene) is the monomer, and the corresponding linear polymer is called high-density polyethylene (HDPE). HDPE is composed of macromolecules in which n ranges from 10,000 to 100,000.

If Y and Z represent moles of monomer and polymer respectively, Z is approximately 10-5 Y. This polymer is called polyethylene rather than polymethylene, (-CH2-)n, because ethylene is a stable compound (methylene is not), and it also serves as the synthetic precursor of the polymer. The two open bonds remaining at the ends of the long chain of carbons (colored magenta) are normally not specified, because the atoms or groups found there depend on the chemical process used for polymerization. The synthetic methods used to prepare this and other polymers will be described later in this chapter.

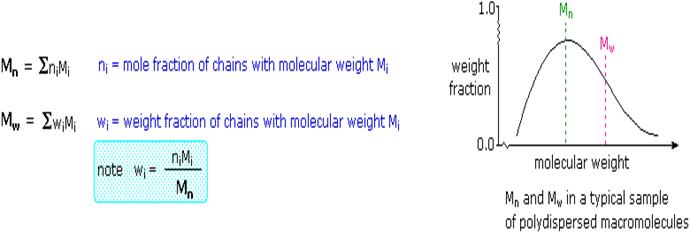

Unlike simpler pure compounds, most polymers are not composed of identical molecules. The HDPE molecules, for example, are all long carbon chains, but the lengths may vary by thousands of monomer units. Because of this, polymer molecular weights are usually given as averages. Two experimentally determined values are common: Mn , the number average molecular weight, is calculated from the mole fraction distribution of different sized molecules in a sample, and Mw , the weight average molecular weight, is calculated from the weight fraction distribution of different sized molecules. These are defined below. Since larger molecules in a sample weigh more than smaller molecules, the weight average Mw is necessarily skewed to higher values, and is always greater than Mn. As the weight dispersion of molecules in a sample narrows, Mw approaches Mn, and in the unlikely case that all the polymer molecules have identical weights (a pure mono-disperse sample), the ratio Mw / Mn becomes unity.

The influence of different mass distributions on Mn and Mw may be examined with the aid of a simple mass calculator. |

Many polymeric materials having chain-like structures similar to polyethylene are known. Polymers formed by a straightforward linking together of monomer units, with no loss or gain of material, are called addition polymers or chain-growth polymers. A listing of some important addition polymers and their monomer precursors is presented in the following table.

Polymers & Its Application Area:- |

||||

Name(s) |

Formula |

Monomer |

Properties |

Application Area |

Polyethylene |

–(CH2-CH2)n– |

ethylene |

soft, waxy solid |

Film wrap, plastic bags |

Polyethylene |

–(CH2-CH2)n– |

ethylene |

rigid, translucent solid |

Electrical insulation |

Polypropylene |

–[CH2-CH(CH3)]n– |

propylene |

atactic: soft, elastic solid |

Similar to LDPE |

Poly(ethylene |

|

ethylene |

Transparent , solid |

Bottles for soft |

Poly(vinyl chloride) |

–(CH2-CHCl)n– |

vinyl chloride |

strong rigid solid |

Pipes, siding, flooring |

Poly(vinylidene chloride) |

–(CH2-CCl2)n– |

vinylidene chloride |

dense, high-melting solid |

Seat covers, films |

Polystyrene |

–[CH2-CH(C6H5)]n– |

styrene |

hard, rigid, clear solid soluble in organic solvents |

Toys, cabinets |

Polyacrylonitrile |

–(CH2-CHCN)n– |

acrylonitrile |

high-melting solid |

Rugs, blankets |

Polytetrafluoroethylene |

–(CF2-CF2)n– |

tetrafluoroethylene |

resistant, smooth solid |

Non-stick surfaces |

Poly(methyl methacrylate) |

–[CH2-C(CH3)CO2CH3]n– |

methyl methacrylate |

hard, transparent solid |

Lighting covers, signs skylights |

Poly(vinyl acetate) |

–(CH2-CHOCOCH3)n– |

vinyl acetate |

soft, sticky solid |

Latex paints, adhesives |

cis-Polyisoprene |

–[CH2-CH=C(CH3)-CH2]n– |

isoprene |

soft, sticky solid |

Requires vulcanization |

Polychloroprene (cis + trans) |

–[CH2- |

chloroprene |

tough, rubbery solid |

Synthetic rubber |

Polyamides(Nylon) |

|

|

Tough, hard engineering plastic |

Fibers, molded objects |

Polyesters |

|

|

Linear polyesters, fibers, recording tape |

|

Polyesters |

|

|

Cross-linked polyester, paints |

|

Polyesters |

|

|

Cross-linked with styrene and benzoylperoxide, fiberglass boat resin, casting resin |

|

Phenol-formaldehyde |

|

|

Mixed with fillers, |

|

Cellulose acetate |

|

|

Photographic film |

|

Silicones |

|

|

Water-repellent coatings, |

|

Polyurethanes |

|

|

Foams, rigid and |

|

3. Properties of Macromolecules

A comparison of the properties of polyethylene (both LDPE & HDPE) with the natural polymers rubber and cellulose is instructive. As noted above, synthetic HDPE macromolecules have masses ranging from 105 to 106 amu (LDPE molecules are more than a hundred times smaller). Rubber and cellulose molecules have similar mass ranges, but fewer monomer units because of the monomer's larger size. The physical properties of these three polymeric substances differ from each other, and of course from their monomers.

• HDPE is a rigid translucent solid which softens on heating above 100º C, and can be fashioned into various forms including films. It is not as easily stretched and deformed as is LDPE. HDPE is insoluble in water and most organic solvents, although some swelling may occur on immersion in the latter. HDPE is an excellent electrical insulator.

• LDPE is a soft translucent solid which deforms badly above 75º C. Films made from LDPE stretch easily and are commonly used for wrapping. LDPE is insoluble in water, but softens and swells on exposure to hydrocarbon solvents. Both LDPE and HDPE become brittle at very low temperatures (below -80º C). Ethylene, the common monomer for these polymers, is a low boiling (-104º C) gas.

• Natural (latex) rubber is an opaque, soft, easily deformable solid that becomes sticky when heated (above. 60º C), and brittle when cooled below -50º C. It swells to more than double its size in nonpolar organic solvents like toluene, eventually dissolving, but is impermeable to water. The C5H8 monomer isoprene is a volatile liquid (b.p. 34º C).

• Pure cellulose, in the form of cotton, is a soft flexible fiber, essentially unchanged by variations in temperature ranging from -70 to 80º C. Cotton absorbs water readily, but is unaffected by immersion in toluene or most other organic solvents. Cellulose fibers may be bent and twisted, but do not stretch much before breaking. The monomer of cellulose is the C6H12O6 aldohexose D-glucose. Glucose is a water soluble solid melting below 150º C. To account for the differences noted here we need to consider the nature of the aggregate macromolecular structure, or morphology, of each substance. Because polymer molecules are so large, they generally pack together in a non-uniform fashion, with ordered or crystalline-like regions mixed together with disordered or amorphous domains. In some cases the entire solid may be amorphous, composed entirely of coiled and tangled macromolecular chains. Crystallinity occurs when linear polymer chains are structurally oriented in a uniform three-dimensional matrix. In the diagram on the right, crystalline domains are colored blue.

Increased crystallinity is associated with an increase in rigidity, tensile strength and opacity (due to light scattering). Amorphous polymers are usually less rigid, weaker and more easily deformed. They are often transparent.

Three factors that influence the degree of crystallinity are:

i) Chain length

ii) Chain branching

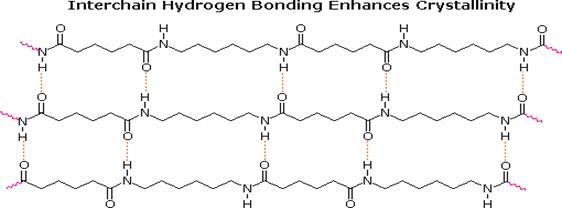

iii) Interchain bonding

The importance of the first two factors is nicely illustrated by the differences between LDPE and HDPE. As noted earlier, HDPE is composed of very long unbranched hydrocarbon chains. These pack together easily in crystalline domains that alternate with amorphous segments, and the resulting material, while relatively strong and stiff, retains a degree of flexibility. In contrast, LDPE is composed of smaller and more highly branched chains which do not easily adopt crystalline structures. This material is therefore softer, weaker, less dense and more easily deformed than HDPE. As a rule, mechanical properties such as ductility, tensile strength, and hardness rise and eventually level off with increasing chain length.

The nature of cellulose supports the above analysis and demonstrates the importance of the third factor (iii). To begin with, cellulose chains easily adopt a stable rod-like conformation. These molecules align themselves side by side into fibers that are stabilized by inter-chain hydrogen bonding between the three hydroxyl groups on each monomer unit. Consequently, crystallinity is high and the cellulose molecules do not move or slip relative to each other. The high concentration of hydroxyl groups also accounts for the facile absorption of water that is characteristic of cotton.

Natural rubber is a completely amorphous polymer. Unfortunately, the potentially useful properties of raw latex rubber are limited by temperature dependence; however, these properties can be modified by chemical change. The cis-double bonds in the hydrocarbon chain provide planar segments that stiffen, but do not straighten the chain. If these rigid segments are completely removed by hydrogenation (H2 & Pt catalyst), the chains lose all constrainment, and the product is a low melting paraffin-like semisolid of little value. If instead, the chains of rubber molecules are slightly cross-linked by sulfur atoms, a process called vulcanization which was discovered by Charles Goodyear in 1839, the desirable elastomeric properties of rubber are substantially improved. At 2 to 3% crosslinking a useful soft rubber, that no longer suffers stickiness and brittleness problems on heating and cooling, is obtained. At 25 to 35% crosslinking a rigid hard rubber product is formed. The following illustration shows a cross-linked section of amorphous rubber. By clicking on the diagram it will change to a display of the corresponding stretched section. The more highly-ordered chains in the stretched conformation are entropically unstable and return to their original coiled state when allowed to relax (click a second time).

On heating or cooling most polymers undergo thermal transitions that provide insight into their morphology. These are defined as the melt transition, Tm , and the glass transition, Tg .

Tm is the temperature at which crystalline domains lose their structure, or melt. As crystallinity increases, so does Tm. Tg is the temperature below which amorphous domains lose the structural mobility of the polymer chains and become rigid glasses. |

Tg often depends on the history of the sample, particularly previous heat treatment, mechanical manipulation and annealing. It is sometimes interpreted as the temperature above which significant portions of polymer chains are able to slide past each other in response to an applied force. The introduction of relatively large and stiff substituents (such as benzene rings) will interfere with this chain movement, thus increasing Tg (note polystyrene below). The introduction of small molecular compounds called plasticizers into the polymer matrix increases the interchain spacing, allowing chain movement at lower temperatures. with a resulting decrease in Tg. The outgassing of plasticizers used to modify interior plastic components of automobiles produces the "new-car smell" to which we are accustomed.

Tm and Tg values for some common addition polymers are listed below. Note that cellulose has neither a Tm nor a Tg.

Polymer |

LDPE |

HDPE |

PP |

PVC |

PS |

PAN |

PTFE |

PMMA |

Rubber |

Tm (ºC) |

110 |

130 |

175 |

180 |

175 |

>200 |

330 |

180 |

30 |

Tg (ºC) |

_110 |

_100 |

_10 |

80 |

90 |

95 |

_110 |

105 |

_70 |

Rubber is a member of an important group of polymers called elastomers. Elastomers are amorphous polymers that have the ability to stretch and then return to their original shape at temperatures above Tg. This property is important in applications such as gaskets and O-rings, so the development of synthetic elastomers that can function under harsh or demanding conditions remains a practical goal. At temperatures below Tg elastomers become rigid glassy solids and lose all elasticity. A tragic example of this caused the space shuttle Challenger disaster. The heat and chemical resistant O-rings used to seal sections of the solid booster rockets had an unfortunately high Tg near 0 ºC. The unexpectedly low temperatures on the morning of the launch were below this Tg, allowing hot rocket gases to escape the seals.

4. Regio and Stereoisomerization in Macromolecules

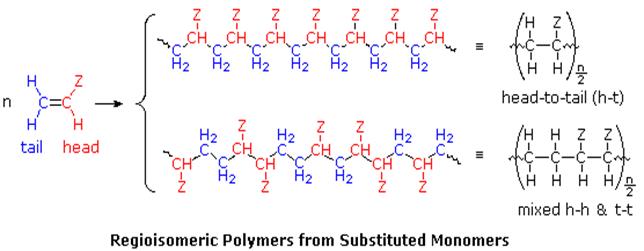

Symmetrical monomers such as ethylene and tetrafluoroethylene can join together in only one way. Monosubstituted monomers, on the other hand, may join together in two organized ways, described in the following diagram, or in a third random manner. Most monomers of this kind, including propylene, vinyl chloride, styrene, acrylonitrile and acrylic esters, prefer to join in a head-to-tail fashion, with some randomness occurring from time to time. The reasons for this regioselectivity will be discussed in the synthetic methods section.

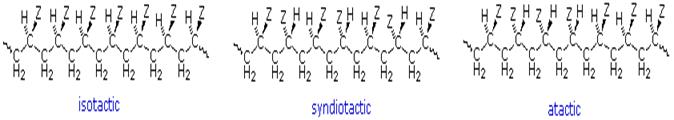

If the polymer chain is drawn in a zig-zag fashion, as shown above, each of the substituent groups (Z) will necessarily be located above or below the plane defined by the carbon chain. Consequently we can identify three configurational isomers of such polymers. If all the substituents lie on one side of the chain the configuration is called isotactic. If the substituents alternate from one side to another in a regular manner the configuration is termed syndiotactic. Finally, a random arrangement of substituent groups is referred to as atactic. Examples of these configurations are shown here.

Many common and useful polymers, such as polystyrene, polyacrylonitrile and poly(vinyl chloride) are atactic as normally prepared. Customized catalysts that effect stereoregular polymerization of polypropylene and some other monomers have been developed, and the improved properties associated with the increased crystallinity of these products has made this an important field of investigation. The following values of Tg have been reported.

Polymer |

Tg atactic |

Tg isotactic |

Tg syndiotactic |

PP |

–20 ºC |

0 ºC |

–8 ºC |

PMMA |

100 ºC |

130 ºC |

120 ºC |

The properties of a given polymer will vary considerably with its tacticity. Thus, atactic polypropylene is useless as a solid construction material, and is employed mainly as a component of adhesives or as a soft matrix for composite materials. In contrast, isotactic polypropylene is a high-melting solid (ca. 170 ºC) which can be molded or machined into structural components.

Synthesis of Addition Polymers

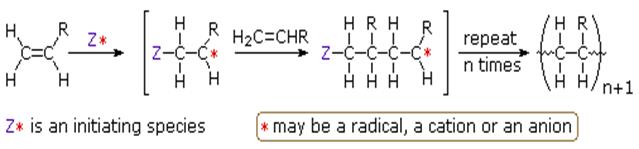

All the monomers from which addition polymers are made are alkenes or functionally substituted alkenes. The most common and thermodynamically favored chemical transformations of alkenes are addition reactions. Many of these addition reactions are known to proceed in a stepwise fashion by way of reactive intermediates, and this is the mechanism followed by most polymerizations. A general diagram illustrating this assembly of linear macromolecules, which supports the name chain growth polymers, is presented here. Since a pi-bond in the monomer is converted to a sigma-bond in the polymer, the polymerization reaction is usually exothermic by 8 to 20 kcal/mol. Indeed, cases of explosively uncontrolled polymerizations have been reported.

It is useful to distinguish four polymerization procedures fitting this general description.

• Radical Polymerization The initiator is a radical, and the propagating site of reactivity is a carbon radical.

• Cationic Polymerization The initiator is an acid, and the propagating site of reactivity is a carbocation.

• Anionic Polymerization The initiator is a nucleophile, and the propagating site of reactivity is a carbanion.

• Coordination Catalytic Polymerization The initiator is a transition metal complex, and the propagating site of reactivity is a terminal catalytic complex.

1. Radical Chain-Growth Polymerization

Virtually all of the monomers described above are subject to radical polymerization. Since this can be initiated by traces of oxygen or other minor impurities, pure samples of these compounds are often "stabilized" by small amounts of radical inhibitors to avoid unwanted reaction. When radical polymerization is desired, it must be started by using a radical initiator, such as a peroxide or certain azo compounds. The formulas of some common initiators, and equations showing the formation of radical species from these initiators are presented below.

By using small amounts of initiators, a wide variety of monomers can be polymerized. One example of this radical polymerization is the conversion of styrene to polystyrene, shown in the following diagram. The first two equations illustrate the initiation process, and the last two equations are examples of chain propagation. Each monomer unit adds to the growing chain in a manner that generates the most stable radical. Since carbon radicals are stabilized by substituents of many kinds, the preference for head-to-tail regioselectivity in most addition polymerizations is understandable. Because radicals are tolerant of many functional groups and solvents (including water), radical polymerizations are widely used in the chemical industry.

To see an animated model of the radical chain-growth polymerization of vinyl chloride

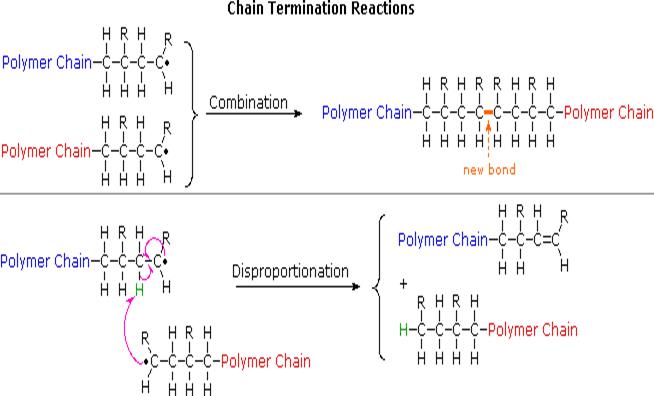

In principle, once started a radical polymerization might be expected to continue unchecked, producing a few extremely long chain polymers. In practice, larger numbers of moderately sized chains are formed, indicating that chain-terminating reactions must be taking place. The most common termination processes are Radical Combination and Disproportionation. These reactions are illustrated by the following equations. The growing polymer chains are colored blue and red, and the hydrogen atom transferred in disproportionation is colored green. Note that in both types of termination two reactive radical sites are removed by simultaneous conversion to stable product(s). Since the concentration of radical species in a polymerization reaction is small relative to other reactants (e.g. monomers, solvents and terminated chains), the rate at which these radical-radical termination reactions occurs is very small, and most growing chains achieve moderate length before termination.

The relative importance of these terminations varies with the nature of the monomer undergoing polymerization. For acrylonitrile and styrene combination is the major process. However, methyl methacrylate and vinyl acetate are terminated chiefly by disproportionation.

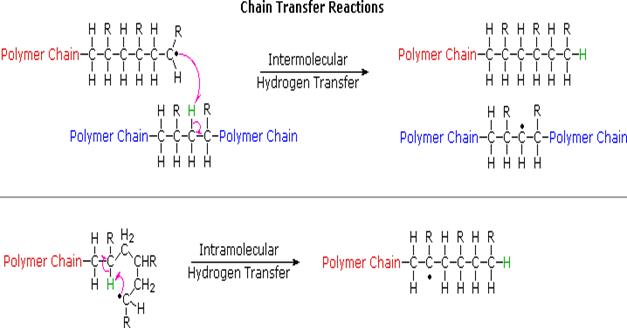

Another reaction that diverts radical chain-growth polymerizations from producing linear macromolecules is called chain transfer. As the name implies, this reaction moves a carbon radical from one location to another by an intermolecular or intramolecular hydrogen atom transfer (colored green). These possibilities are demonstrated by the following equations

Chain transfer reactions are especially prevalent in the high pressure radical polymerization of ethylene, which is the method used to make LDPE (low density polyethylene). The 1º-radical at the end of a growing chain is converted to a more stable 2º-radical by hydrogen atom transfer. Further polymerization at the new radical site generates a side chain radical, and this may in turn lead to creation of other side chains by chain transfer reactions. As a result, the morphology of LDPE is an amorphous network of highly branched macromolecules.

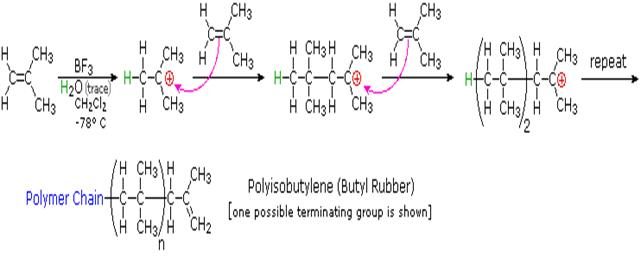

2. Cationic Chain-Growth Polymerization

Polymerization of isobutylene (2-methylpropene) by traces of strong acids is an example of cationic polymerization. The polyisobutylene product is a soft rubbery solid, Tg = _70º C, which is used for inner tubes. This process is similar to radical polymerization, as demonstrated by the following equations. Chain growth ceases when the terminal carbocation combines with a nucleophile or loses a proton, giving a terminal alkene (as shown here).

Monomers bearing cation stabilizing groups, such as alkyl, phenyl or vinyl can be polymerized by cationic processes. These are normally initiated at low temperature in methylene chloride solution. Strong acids, such as HClO4 , or Lewis acids containing traces of water (as shown above) serve as initiating reagents. At low temperatures, chain transfer reactions are rare in such polymerizations, so the resulting polymers are cleanly linear (unbranched).

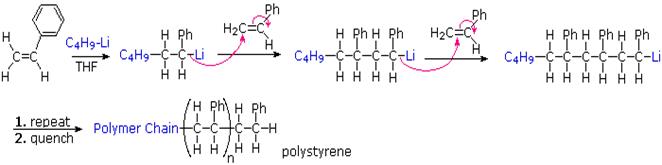

3. Anionic Chain-Growth Polymerization

Treatment of a cold THF solution of styrene with 0.001 equivalents of n-butyllithium causes an immediate polymerization. This is an example of anionic polymerization, the course of which is described by the following equations. Chain growth may be terminated by water or carbon dioxide, and chain transfer seldom occurs. Only monomers having anion stabilizing substituents, such as phenyl, cyano or carbonyl are good substrates for this polymerization technique. Many of the resulting polymers are largely isotactic in configuration, and have high degrees of crystallinity.

Species that have been used to initiate anionic polymerization include alkali metals, alkali amides, alkyl lithiums and various electron sources. A practical application of anionic polymerization occurs in the use of superglue. This material is methyl 2-cyanoacrylate, CH2=C(CN)CO2CH3. When exposed to water, amines or other nucleophiles, a rapid polymerization of this monomer takes place.

4. Ziegler-Natta Catalytic Polymerization

An efficient and stereospecific catalytic polymerization procedure was developed by Karl Ziegler (Germany) and Giulio Natta (Italy) in the 1950's. Their findings permitted, for the first time, the synthesis of unbranched, high molecular weight polyethylene (HDPE), laboratory synthesis of natural rubber from isoprene, and configurational control of polymers from terminal alkenes like propene (e.g. pure isotactic and syndiotactic polymers). In the case of ethylene, rapid polymerization occurred at atmospheric pressure and moderate to low temperature, giving a stronger (more crystalline) product (HDPE) than that from radical polymerization (LDPE). For this important discovery these chemists received the 1963 Nobel Prize in chemistry.

Ziegler-Natta catalysts are prepared by reacting certain transition metal halides with organometallic reagents such as alkyl aluminum, lithium and zinc reagents. The catalyst formed by reaction of triethylaluminum with titanium tetrachloride has been widely studied, but other metals (e.g. V & Zr) have also proven effective. The following diagram presents one mechanism for this useful reaction. Others have been suggested, with changes to accommodate the heterogeneity or homogeneity of the catalyst. Polymerization of propylene through action of the titanium catalyst gives an isotactic product; whereas, a vanadium based catalyst gives a syndiotactic product.

Copolymers

The synthesis of macromolecules composed of more than one monomeric repeating unit has been explored as a means of controlling the properties of the resulting material. In this respect, it is useful to distinguish several ways in which different monomeric units might be incorporated in a polymeric molecule. The following examples refer to a two component system, in which one monomer is designated A and the other B.

Statistical Copolymers |

Also called random copolymers. Here the monomeric units are distributed randomly, and sometimes unevenly, in the polymer chain: ~ABBAAABAABBBABAABA~. |

Alternating Copolymers |

Here the monomeric units are distributed in a regular alternating fashion, with nearly equimolar amounts of each in the chain: ~ABABABABABABABAB~. |

Block Copolymers |

Instead of a mixed distribution of monomeric units, a long sequence or block of one monomer is joined to a block of the second monomer: |

Graft Copolymers |

As the name suggests, side chains of a given monomer are attached to the main chain of the second monomer: ~AAAAAAA(BBBBBBB~)AAAAAAA(BBBB~)AAA~. |

1. Addition Copolymerization

Most direct copolymerizations of equimolar mixtures of different monomers give statistical copolymers, or if one monomer is much more reactive a nearly homopolymer of that monomer. The copolymerization of styrene with methyl methacrylate, for example, proceeds differently depending on the mechanism. Radical polymerization gives a statistical copolymer. However, the product of cationic polymerization is largely polystyrene, and anionic polymerization favors formation of poly(methyl methacrylate). In cases where the relative reactivities are different, the copolymer composition can sometimes be controlled by continuous introduction of a biased mixture of monomers into the reaction.

Formation of alternating copolymers is favored when the monomers have different polar substituents (e.g. one electron withdrawing and the other electron donating), and both have similar reactivities toward radicals. For example, styrene and acrylonitrile copolymerize in a largely alternating fashion.

Useful Copolymers :- |

|||

Monomer A |

Monomer B |

Copolymer |

Uses |

H2C=CHCl |

H2C=CCl2 |

Saran |

films & fibers |

H2C=CHC6H5 |

H2C=C-CH=CH2 |

SBR styrene butadiene rubber |

Tires |

H2C=CHCN |

H2C=C-CH=CH2 |

Nitrile Rubber |

adhesives |

H2C=C(CH3)2 |

H2C=C-CH=CH2 |

Butyl Rubber |

inner tubes |

F2C=CF(CF3) |

H2C=CHF |

Viton |

Gaskets |

A terpolymer of acrylonitrile, butadiene and styrene, called ABS rubber, is used for high-impact containers, pipes and gaskets.

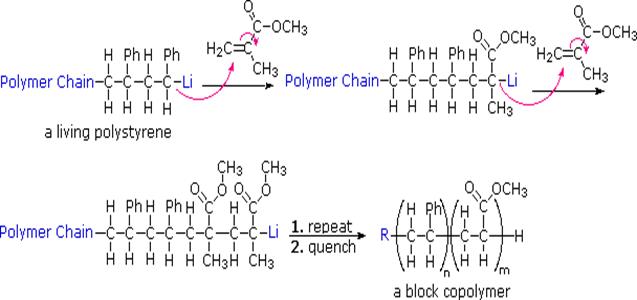

2. Block Copolymerization

Several different techniques for preparing block copolymers have been developed, many of which use condensation reactions (next section). At this point, our discussion will be limited to an application of anionic polymerization. In the anionic polymerization of styrene described above, a reactive site remains at the end of the chain until it is quenched. The unquenched polymer has been termed a living polymer, and if additional styrene or a different suitable monomer is added a block polymer will form. This is illustrated for methyl methacrylate in the following diagram.

Condensation Polymers

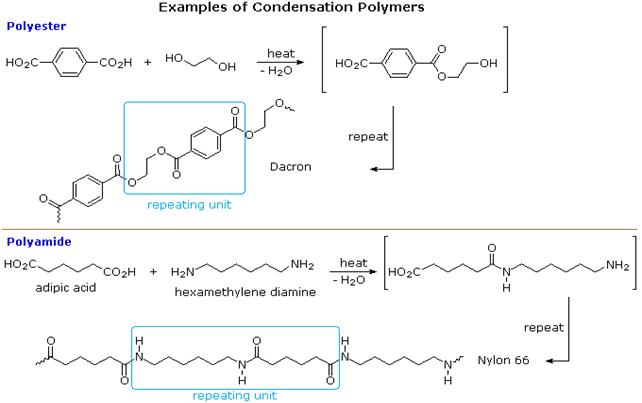

A large number of important and useful polymeric materials are not formed by chain-growth processes involving reactive species such as radicals, but proceed instead by conventional functional group transformations of polyfunctional reactants. These polymerizations often (but not always) occur with loss of a small byproduct, such as water, and generally (but not always) combine two different components in an alternating structure. The polyester Dacron and the polyamide Nylon 66, shown here, are two examples of synthetic condensation polymers, also known as step-growth polymers. In contrast to chain-growth polymers, most of which grow by carbon-carbon bond formation, step-growth polymers generally grow by carbon-heteroatom bond formation (C-O & C-N in Dacron & Nylon respectively). Although polymers of this kind might be considered to be alternating copolymers, the repeating monomeric unit is usually defined as a combined moiety.

Examples of naturally occurring condensation polymers are cellulose, the polypeptide chains of proteins, and poly(β-hydroxybutyric acid), a polyester synthesized in large quantity by certain soil and water bacteria. Formulas for these will be displayed below by clicking on the diagram.

1. Characteristics of Condensation Polymers

Condensation polymers form more slowly than addition polymers, often requiring heat, and they are generally lower in molecular weight. The terminal functional groups on a chain remain active, so that groups of shorter chains combine into longer chains in the late stages of polymerization. The presence of polar functional groups on the chains often enhances chain-chain attractions, particularly if these involve hydrogen bonding, and thereby crystallinity and tensile strength. The following examples of condensation polymers are illustrative.

Note that for commercial synthesis the carboxylic acid components may actually be employed in the form of derivatives such as simple esters. Also, the polymerization reactions for Nylon 6 and Spandex do not proceed by elimination of water or other small molecules. Nevertheless, the polymer clearly forms by a step-growth process.

Condensation Polymers :- |

||||

Formula |

Type |

Components |

Tg ºC |

Tm ºC |

~[CO(CH2)4CO-OCH2CH2O]n~ |

polyester |

HO2C-(CH2)4-CO2H |

< 0 |

50 |

|

polyester |

para HO2C-C6H4-CO2H |

70 |

265 |

|

polyester |

meta HO2C-C6H4-CO2H |

50 |

240 |

|

polycarbonate |

(HO-C6H4-)2C(CH3)2 |

150 |

267 |

|

polyamide |

HO2C-(CH2)4-CO2H |

45 |

265 |

|

polyamide |

|

53 |

223 |

|

polyamide |

para HO2C-C6H4-CO2H |

--- |

500 |

|

polyamide |

meta HO2C-C6H4-CO2H |

273 |

390 |

|

polyurethane |

HOCH2CH2OH |

52 |

--- |

The difference in Tg and Tm between the first polyester (completely aliphatic) and the two nylon polyamides (5th & 6th entries) shows the effect of intra-chain hydrogen bonding on crystallinity. The replacement of flexible alkylidene links with rigid benzene rings also stiffens the polymer chain, leading to increased crystalline character, as demonstrated for polyesters (entries 1, 2 &3) and polyamides (entries 5, 6, 7 & 8). The high Tg and Tm values for the amorphous polymer Lexan are consistent with its brilliant transparency and glass-like rigidity. Kevlar and Nomex are extremely tough and resistant materials, which find use in bullet-proof vests and fire resistant clothing.

Many polymers, both addition and condensation, are used as fibers The chief methods of spinning synthetic polymers into fibers are from melts or viscous solutions. Polyesters, polyamides and polyolefins are usually spun from melts, provided the Tm is not too high. Polyacrylates suffer thermal degradation and are therefore spun from solution in a volatile solvent. Cold-drawing is an important physical treatment that improves the strength and appearance of these polymer fibers. At temperatures above Tg, a thicker than desired fiber can be forcibly stretched to many times its length; and in so doing the polymer chains become untangled, and tend to align in a parallel fashion. This cold-drawing procedure organizes randomly oriented crystalline domains, and also aligns amorphous domains so they become more crystalline. In these cases, the physically oriented morphology is stabilized and retained in the final product. This contrasts with elastomeric polymers, for which the stretched or aligned morphology is unstable relative to the amorphous random coil morphology.

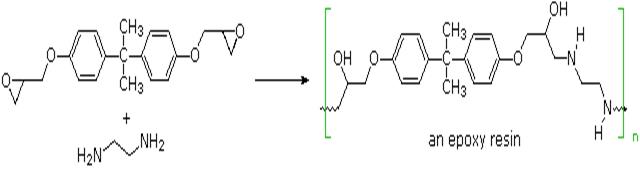

Step-growth polymerization is also used for preparing a class of adhesives and amorphous solids called epoxy resins. Here the covalent bonding occurs by an SN2 reaction between a nucleophile, usually an amine, and a terminal epoxide. In the following example, the same bisphenol A intermediate used as a monomer for Lexan serves as a difunctional scaffold to which the epoxide rings are attached. Bisphenol A is prepared by the acid-catalyzed condensation of acetone with phenol.

Thermosetting vs. Thermoplastic Polymers:-

Most of the polymers described above are classified as thermoplastic. This reflects the fact that above Tg they may be shaped or pressed into molds, spun or cast from melts or dissolved in suitable solvents for later fashioning. Because of their high melting point and poor solubility in most solvents, Kevlar and Nomex proved to be a challenge, but this was eventually solved.

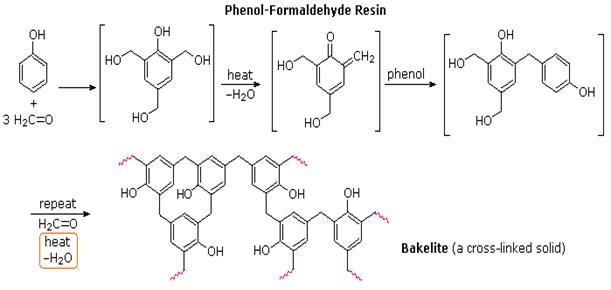

Another group of polymers, characterized by a high degree of cross-linking, resist deformation and solution once their final morphology is achieved. Such polymers are usually prepared in molds that yield the desired object. Because these polymers, once formed, cannot be reshaped by heating, they are called thermosets .Partial formulas for four of these will be shown below by clicking the appropriate button. The initial display is of Bakelite, one of the first completely synthetic plastics to see commercial use (circa 1910).

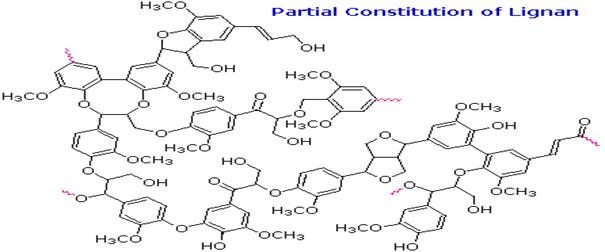

A natural resinous polymer called lignin has a cross-linked structure similar to bakelite. Lignin is the amorphous matrix in which the cellulose fibers of wood are oriented. Wood is a natural composite material, nature's equivalent of fiberglass and carbon fiber composites. A partial structure for lignan is shown here

Source: http://www.astra-polymers.com/docs/PolymerIntroduction.doc

Web site to visit: http://www.astra-polymers.com/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes