Chapter 1.

General Introduction

1.1 What is Manufacturing (mfg)?

- Manufacturing is the process of converting raw materials into products by means of various processes, machinery, and operations, through a well-organized plan for each activity required. (sheet metal for appliances and car bodies, machines to make bolts and nuts, sewing machines to make clothing).

- The higher the level of mfg activity in a country, the higher the standard of living of its people.

- Manufacturing has the important function of adding a value to a manufactured product. For example: when clay is made into the ceramic part of a spark plug, a vase, a cutting tool, or in electrical insulator, value is added to the clay (value added).

- Manufacturing may produce discrete products (individual parts: nails, balls, cans) or continuous products (sheet metal, wire, plastic tubing) which are then cut into individual pieces to become discrete products.

- Manufacturing involves a wide variety of resources and activities:

- Product design, machinery and tooling, process planning.

- Selection of raw materials, purchasing.

- Manufacturing, production control, support services.

- Marketing, sales, shipping, and customer service.

- Manufacturing activities must be responsive to several demands and trends:

- A product must fully meet design requirements, product specifications, and standards.

- A product must be manufactured by the most economical and environmentally friendly methods.

- Quality must be built into the product at each stage from design to assembly, rather than tested after the product is completed.

- Production methods must be flexible enough to respond to changes in market demands, types of products, production rates, production quantities, and on-time delivery to customer.

- Continuous developments in materials, production methods, and computer integration of both technological and managerial activities in a mfg organization must constantly be evaluated with a view to their appropriate, timely, & economical implementation.

- Manufacturing activities must be viewed as a large system, all parts of which are interrelated. Such systems can be modeled in order to study the effects of factors such as changes in market demands, product design, materials, and production methods on quality and cost.

- The manufacturer must work with the customer for timely feedback to continuous product improvement.

- Manufacturing organization constantly must strive for higher levels of quality and productivity (defined as the optimum use of all its resources). Output per employee per hour in all phases must be maximized.

1.1.1 Brief history of manufacturing: (not covered)

Example 1.1 Paper clips (mfg product):

Example 1.1 Paper clips (mfg product):

Identify factors that are involved in the design and mfg of paper clips:

- What type of material? Metallic or non metallic?

- If you choose a metal, what type of metal and in what condition?

- If the material that you start with is wire, what should be its diameter? Should it be round or other cross-section?

- Is the wire’s surface finish & appearance important? What should be its roughness?

- How would you take a piece of wire & shape it into a paper clip? Would you do it by hand? If not, what kind of machine should you design and make or purchase to make paper clips?

- If, as the owner of a company, you were given an order for 10,000 paper clips vs. an order for millions of clips, would your approach to mfg differently?

Functional requirements:

- Hold pieces of paper together with sufficient clamping force; papers do not slip away. So, clips must be properly designed in shape, size, feel, and appearance.

- Material selected must have a certain stiffness & strength.

- If the yield stress is too low, the clip will bend permanently àdifficult to reuse.

- Stiffness also depends on diameter the wire and dimensions of the clip.

Material selection:

- After finalizing the design, a suitable material has to be selected.

- Material selections requires a knowledge of function and service requirements of the product.

- Therefore, choosing materials that are commercially available at the lowest possible cost.

- Corrosion resistance (no decay, no rust, …) must also be considered.

Other questions regarding production of paper clip:

- Will the material selected be able to undergo bending during mfg without cracking or breaking?

- Can the wire be easily cut from a long piece without causing excessive wear on tooling?

- Will the cutting process produce a smooth edge on the wire or it will leave a sharp edge (burr)?

- What is the most economical method of mfg this part at the desired production rate so that it can be competitive?

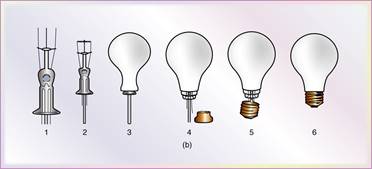

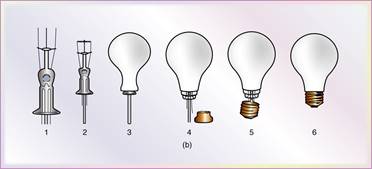

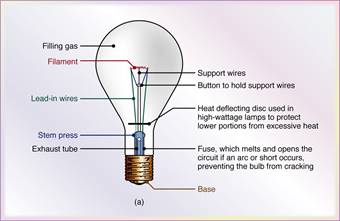

Example 1.2 Incandescent light bulbs - Read:

- See components and manufacturing steps.

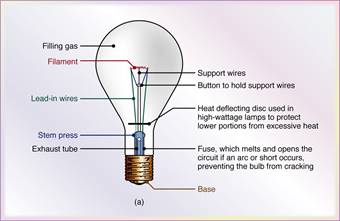

1.2 The Product Design Process and Concurrent Engineering:

- Product design is a critical activity; 70% to 80% of the cost of product development and manufacture is determined by the decisions made in the initial design stages.

- The design process for a product first requires a thorough understanding of the functions & the performance expected of that product.

- The market for a product and its anticipated uses must be defined clearly by market analysts and sales personnel.

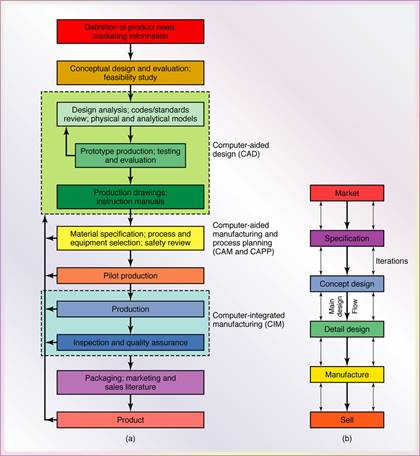

Traditional product cycle

- Design and mfg activities have taken place sequentially (Fig. 4a).

Designers would spend considerable effort and time in analyzing components and preparing detailed part drawings.

Designers would spend considerable effort and time in analyzing components and preparing detailed part drawings.- These drawing would then be forwarded to other departments in the organization, such as materials departments, where particular alloys and vendor sources would be identified.

- The specifications would then be sent to the mfg department, where the detailed drawings would be reviewed and processes selected for efficient production.

- While this approach seems logical and straightforward in theory, it has been found in practice to be extremely wasteful of resources.

- For example, a mfg engineer may wish to taper the flange on a part to improve its castability or may decide that a different alloy is desirable; such changes necessitate a repeat of the design analysis stage in order to ensure that the product will still function satisfactorily. These iterations certainly waste resources, but more importantly, they waste time.

Concurrent Engineering – CE: (or Simultaneous Engineering)

- CE is a systematic approach integrating the design and mfg of products, with a view toward optimizing all elements involved in the life cycle of the product. See Fig. (4b).

- Basic goals of CE:

- Reduce changes in product’s design & engineering.

- Reduce the time and costs involved in taking the product form its design concept to its production and its introduction into the marketplace.

- The concept of life-cycle engineering requires that the entire life of a product be considered in the design stage: the design, production, distribution, usage, and recycling/disposal are considered simultaneously. Thus, a well-designed product is

- functional (design),

- well-manufactured (production),

- well-packaged (distribution),

- durable (functions effectively for its intended life),

- maintainable (has components which can be easily replaced, maintained, or repaired),

- resource-efficient (can be disassembled so that components can be recycled).

- For CE to succeed, it must:

- Have the full support of upper management;

- Have multifunctional and interactive teamwork, including support groups.

- Utilize all available technologies.

- Example of the benefits of CE: One automotive company has reduced the No. of components in one of its engines by 30%, and as a result has decreased the engine weight by 25% and cut its mfg time by 50%.

- Product design often involves preparing analytical and physical models of the product as an aid to studying factors such as forces, stresses, deflections, and optimal part shape. Today, analytical models are highly simplified using:

- CAD (computer-aided modeling and design): the use of computers in interactive engineering drawing and storage of designs. Programs complete the layout, geometric transformations, projections, rotations, magnifications, and interval (cross-section) views of a part and its relationship with other part.

- CAE (computer-aided engineering), the performance of structures subjected to static or dynamic loads and to varying temperatures can now be simulated, analyzed, and tested efficiently, accurately, and rapidly. The information developed can be stored, retrieved, displayed, printed, and transferred any where in the organization. Designs can be optimized, and modifications can be made, directly and easily, at any time.

- CAM (computer-aided manufacturing) involves all phases of manufacturing, by utilizing and processing further the large amounts of information on materials and processes gathered and stored in the organization’s database.

- The next step in the production process is to make and test a prototype. An important technology is rapid prototyping, which relies on CAD/CAM and other techniques to produce prototypes rapidly and at low cost.

- Tests of prototypes must be designed to simulate as closely as possible the conditions under which the product is to be used (temp., humidity, vibration, misuse,..). During testing of prototypes, modifications in the original design, materials, or production methods may be necessary.

- After this phase has been completed, appropriate process plans, mfg methods, equipment, and tooling are selected, with the cooperation of mfg engineers, process planners, and others involved in production.

- Note: visual prototyping is a totally software form of prototyping, and uses advanced graphics and virtual-reality environments to allow designers to examine a part.

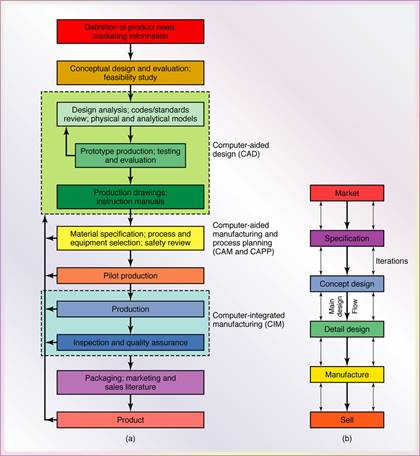

1.3 Design for Manufacture, Assembly, Disassembly, and Service - (DFM, DFA, DFS):

- DFM is a comprehensive approach to production of goods, and it integrates the design process with materials, mfg methods, process planning, assembly, testing, and quality assurance such that the product can be manufactured economically and efficiently

- Establishing quantitative relationships is essential in order to optimize the design for ease of mfg and assembly at minimum product cost. Expert systems (ES), which have optimization capabilities and thus can expedite the iteration process in design optimization, are powerful tools in such analysis.

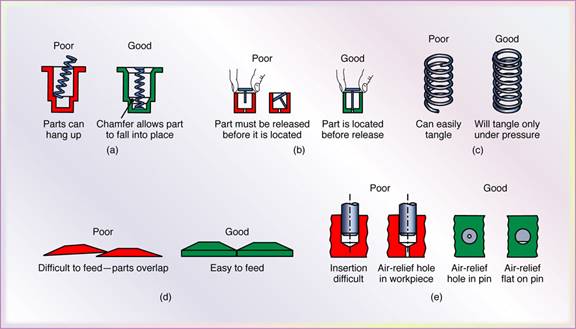

- Assembly is an important phase of the overall mfg operation and requires consideration of the ease, speed, and cost of putting parts together (see Fig. 1.5 – redesign of parts to facilitate assembly).

- Also, products must be designed so that disassembly is possible, in order to enable the product to be taken apart easily for maintenance, servicing, or recycling of its components. This contributes significantly to product cost, so DFA (and design for disassembly) are important aspects of manufacturing.

- Design for service, the goal of which is that individual parts or sub-assemblies in a product be easy to reach and service.

- The trend now is to combine DFM and DFA into the more comprehensive DFMA, which recognizes the inherent interrelationship among the manufacturing of components and their assembly into a final product.

1.4 Selecting Materials

- The following are the general types of materials used in mfg (either individually or as composites):

- Ferrous metals: carbon- alloy steels, stainless steels, and tool and die steels.

- Nonferrous metals: aluminum, magnesium, copper, nickel, titanium, low-melting alloys, beryllium, zirconium, etc.

- Plastics (Polymers): thermoplastics, thermosets, and elastomers.

- Ceramics, glasses, glass ceramics, graphite, diamond, and diamond-like materials.

- Composite (engineered) materials: reinforced plastics, metal-matrix and ceramic-matrix composites.

- Nanomaterials: shape-memory alloys, amorphous alloys, semiconductor, and superconductors.

1.4.1 Properties of materials

- When selecting materials for products:

- First consider their mechanical properties: strength, toughness, ductility, hardness, elasticity, fatigue, and creep.

- Next consider the physical properties of materials: density, specific heat, thermal expansion and conductivity, melting point, and electrical magnetic properties.

- Combination of mechanical and physical properties: strength-to-weight ratio and stiffness-to-weight ratio. Such properties are important for aerospace, automotive, and sport applications. Aluminum, titanium, reinforced plastics are good examples.

- Chemical properties also play a significant role, both in hostile and in normal environments: oxidation, corrosion, toxicity, and flammability.

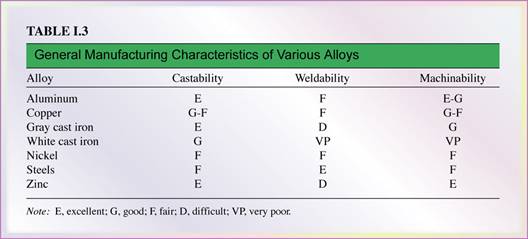

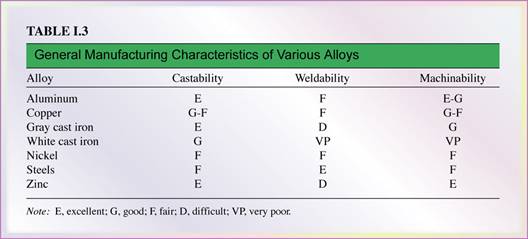

- Manufacturing properties of materials determine whether they can be cast, formed, machined, welded, & heat-treated with relative ease (see table below). Methods used to process materials to desired shapes can affect product’s performance, service life, & cost.

1.4.2 Cost and Availability

- The economic aspects of material selection are as important as technological considerations of properties & characteristics of materials.

- A product design can be modified to take advantage of standard dimensions of raw materials and thus avoid extra mfg costs.

- Reliability of supply, as well as demand, affects cost.

- Different costs are involved in processing materials by different methods. Some methods require expensive machinery, others require extensive labor, and still others require personnel with special skills, a high level of education, or specialized training.

1.4.3 Appearance, Service Life, and Recycling

- Color, feel, and surface texture are characteristics that we consider when making a decision about purchasing a product.

- Time- & service- dependent phenomena such as wear, fatigue, creep, and dimensional stability are important and if not controlled can lead to malfunction or failure of the product. Friction & wear, corrosion, and other phenomena can shorten product’s life or cause it to fail prematurely.

- To keep clean and healthy environment, recycling (or proper disposal) of component materials at the end of product’s useful service life and proper treatment and disposal of toxic wastes have become major considerations.

Examples 1.3 & 1.4 - Read:

- Selecting Manufacturing Processes

1.5.1 Types of mfg Processes

- There is usually more than one method of manufacturing a part from a given material:

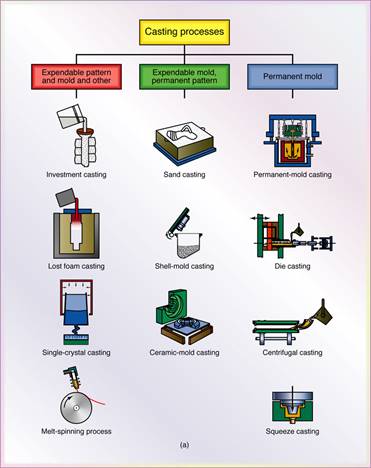

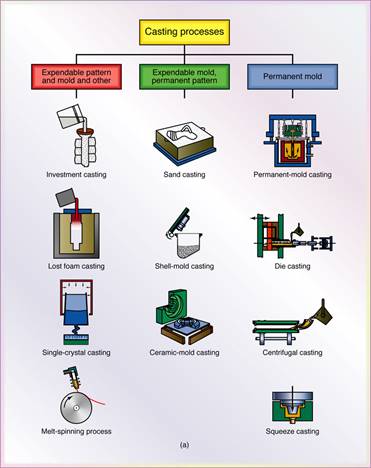

Casting: expendable mold & permanent mold (see Fig. 1.7a)

Casting: expendable mold & permanent mold (see Fig. 1.7a)

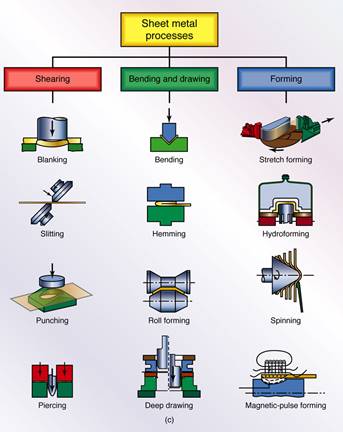

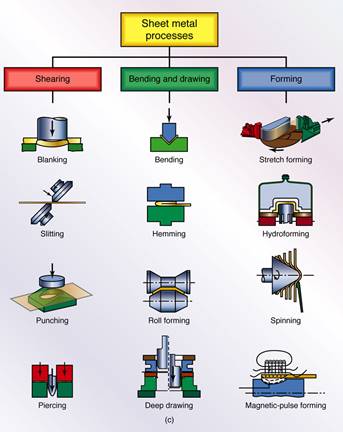

- Forming and shaping: rolling, forging, extrusion, drawing, sheet forming, powder metallurgy, and molding (see Figs. 1.7b-1.7d).

- Machining: turning, boring, drilling, milling, planing, shaping, broaching, and grinding, ultrasonic machining; chemical, electrical, electrochemical machining; and high-energy-beam machining (Fig.17e).

- Joining: welding, brazing, soldering, diffusion bonding, adhesive bonding, and mechanical joining (Fig. 1.7f).

- Finishing: honing, laping, polishing, burnishing, deburring, surface treating, coating, and plating (Fig. 1.7e).

- Nanofabrication: it is the most advanced technology and is capable of producing parts with dimensions at the nano level (one billionth); processes such as etching techniques, electron-beams, and laser beams. Present applications are in the fabrication of microelectromechanical systems (MEMS) and extending to nanoelectromechanical systems (NEMS).

- Selecting a mfg process (s) depends not only on the shape to be produced but also material properties. Brittle and hard materials, for example, cannot be shaped or formed easily, where-as they can be cast, machined, or ground.

- The mfg process usually alters the properties of materials. Metals that are formed at room temperature become stronger, harder, and less ductile than they were before processing.

- Each mfg process has its own advantages and limitations, as well as production rates and product cost.

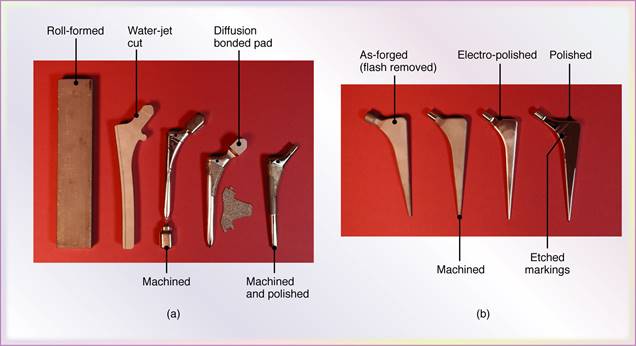

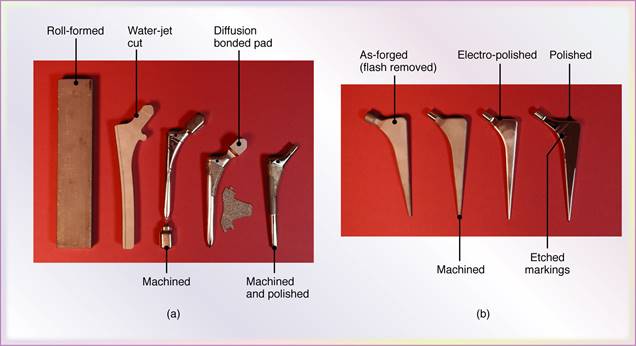

(a) Manufacturing steps in the production of a roll-formed and machined total hip replacement stem; (b) Manufacturing steps in the production of a forged stem. Hip stems can also be produced by investment casting, metal injection molding, insert injection molding, and assorted other processes

1.5.2 Dimensional accuracy and surface finish:

- The dimensions and shape complexity of part have a major bearing on the mfg process selected to produce it:

- Flat parts with thin cross-sections cannot be cast properly.

- Complex parts cannot be formed easily and economically, whereas they may be cast or else fabricated from individual pieces.

- Tolerances and surface finish obtained in hot-working operations cannot be as good as those obtained in cold-working operations because of dimensional changes, warping, and oxidation during processing of materials at elevated temperatures.

- Some casting processes produce a better surface finish than others because of the different types of mold materials used.

1.5.3 Operational and manufacturing costs:

- The design & cost of tooling, lead time required to begin production & the effect of work piece material on tool life and die life are major consideration.

- For parts made from expensive materials, the lower the scrap rate, the more economical the production process will be; i.e.; minimize waste.

- Availability of machines and equipment within the mfg facility, and the experience of operating personnel are also important cost factors. If these capabilities are not available, some parts have to be manufactured by outside companies (outsourcing).

- No. of parts required and the production rate are important in determining the processes to be used and the economics of production. Small-batch production involves annual quantities about 10 to 100. Batch production usually involves lot sizes 100 to 5000, and mass production in lots sizes often over 100,000 using special-purpose machinery.

- The particular mfg process and operation of machinery has significant environmental & safety implications.

- The safe use of machinery is another important consideration.

1.5.4 Consequences of improper selection of materials & processes:

- A component or a product is generally considered to have failed when:

- It stops functioning (broken shaft, gear, bolt, or turbine blade).

- It does not function properly or perform within required specification limits (worn bearings, gears, tools, and dies).

- It becomes unreliable or unsafe for further use (crack in a shaft, poor connection in a printed-circuit board, or delamination of a reinforced plastic component).

- Product failures may result from: design deficiencies, improper material selection, material defect, manufacturing-induced defects, improper component assembly, and improper product use.

1.5.5 Net-shape manufacturing:

- Additional processes (subsequent to original one) may be necessary to get the designed dimensions and tolerance, and desired surface finish (forged part may need to be machined or grinded).

- These additional processes can significantly raise the cost of a product. Consequently, the concept of net-shape or near-net-shape manufacturing has become very important, in which by the first operation the part is made as close to the final desired dimensions, tolerances, surface finish , and specifications as possible.

Examples 1.6 - Read:

- Environmentally-Conscious Design and Manufacturing

- Plastics, aluminum, lubricants and coolants, and many by-products are discarded every year. Many of such activities adversely affect the environment.

- Some of the guidelines that should be considered when we carefully analyze the products, their design, materials used, and waste produced:

- Reduce waste of materials by refinements in the design and reducing amount of materials used.

- Reduce the use of hazardous materials in products and mfg processes.

- Ensure proper handling and disposal of all waste.

- Make improvement in recycling, waste treatment, and reuse of materials.

- Conduct research and development into environmentally safe products and into mfg technology.

- A major emphasis is on design for the environment (DFE) or green design. This approach anticipates the possible negative environmental impact of materials, products, & processes, so that it can be taken into account at the earliest stages of design and mfg.

- The main objectives now are preventing pollution at the source and promoting recycling and reuse instead of disposal. These goals lead to design for recycling (DFR): Making improvements in recycling, in waste treatment, and in reuse of materials.

- In the U.S. automotive industry, 9 millions passenger cars and about 300 million tires are discarded each year; about 100 million of those tires are reused in various ways. About 75% of car parts, mostly metals, are now recycled.

- The ISO 14000 standards concern with environmental management. These standards address what a company can do to minimize harmful environmental effects caused by its activities.

- Computer-Integrated Manufacturing (CIM)

- The use of computers has been extended to computer-integrated mfg (CIM) in which software and hardware are integrated from product concept through product distribution in the marketplace.

- CIM is effective because of its capability for making possible:

- Responsiveness to rapid changes in market demand and product modification.

- Better use of materials, machinery, personnel, & reduction in inventory.

- Better control of production & management of the total mfg operation.

- The manufacture of high-quality products at low cost.

- The following is an outline of the major applications of computers in manufacturing (Ch. 38 & 39):

- Computer Numerical Control (CNC): a method of controlling the movements of machine components by direct insertion of coded instructions in the form of numerical data.

- Adaptive Control (AC): parameters in a mfg process are adjusted automatically to optimize production rate and product quality and to minimize cost. Parameters (forces, temp., dimension, surface finish) are monitored constantly. If they move outside the acceptable range, the system adjusts the process variables until the parameters again fall within the specified range.

- Industrial Robots: replacing humans in operations that are repetitive, boring, and dangerous, thus reducing possibility of human error, decreasing variability in product quality, and decreasing variability in product quality, and improving productivity (sensors). Figure below shows automated spot welding of automobile bodies in a mass production line.

- Automated handling of materials: handling of materials and products in various stages of completion (work in progress). Move from storage to a machine, from machine to machine, and at points of inspection, inventory, and shipment.

- Automated and robotic assembly systems: these systems mainly have replaced costly assembly by human operators, although humans still have to perform some of these operations. Products are now designed or redesigned so that they can be assembled more easily and faster by machines.

- Computer-aided process planning (CAPP): this system is capable of improving productivity in plant by optimizing process plans, reducing planning costs, and improving the consistency of product quality & reliability. Functions such as estimating of cost and the monitoring work standards (time required to perform a certain operation) are also be incorporated into the system.

- Group technology (GT): parts can be grouped and produced by classifying them into families, according to similarities in design and similarities in the mfg processes used. In this way, part designs and process plans can be standardized and families of similar parts can be produced efficiently and economically.

- Just-in-time production (JIT): supplies of raw materials, parts, and components are delivered to the manufacturer JIT to be used, parts and components are produced JIT to be made into subassemblies and assemblies, and products are finished JIT to be delivered to the consumer. In this way, inventory-carrying costs are low, part defects are detected right away, productivity is increased, and high quality products are made at low cost.

- Cellular manufacturing (CM): this system utilizes workstations (mfg cells) that usually contain several production machines controlled by a central robot, each machine performing a different operation on the part.

- Flexible manufacturing systems (FMS): integrate mfg cells into a large unit, all interfaced with a central computer. Although very costly, FMS is capable of efficiently producing parts in small runs and of changing mfg sequences on different parts quickly; this flexibility enables them to meet rapid changes in market demand for various types of products.

- Expert Systems (ES): complex computer programs with the capability to perform various tasks and solve difficult real-life problems much as human experts would.

- Artificial intelligence (AI): use of machines & computers to replace human intelligence. Computer-controlled systems are now capable of learning from experience & of making decisions that optimize operations and minimize costs. Artificial neural networks (ANN), which are designed to simulate the thought processes of human brain, have the capability of modeling & simulating production facilities, monitoring & controlling mfg processes, diagnosing problems in machine performance, conducting financial planning, and managing a company’s mfg strategy.

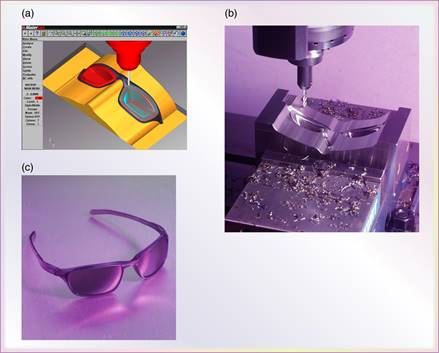

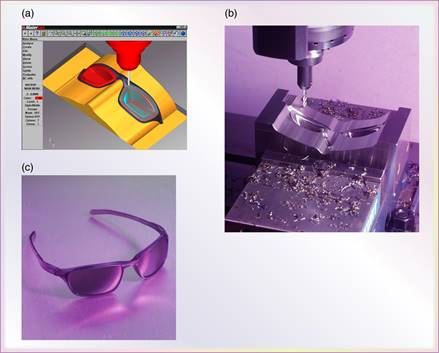

Example 1.7 Application of CAD/CIM to make a mold for sunglasses:

First a model of the sunglass is modeled using a CAD software package. The geometric information is sent to CNC milling machine.

First a model of the sunglass is modeled using a CAD software package. The geometric information is sent to CNC milling machine. - Machining of the die cavity using a CNC milling machine.

- Final product.

- Lean Production and Agile Manufacturing

Lean production (LP)

- LP involves a thorough assessment of each of the activities of a company in order minimize waste at all levels. This includes:

- Efficiency & effectiveness of all its various operations.

- Efficiency of machinery and equipment.

- Number of personal involved in each particular operation.

- The possible dispensing of some of its operations & managers.

- This approach continues with a comprehensive analysis of the costs of each activity, including those due to productive and non-productive labor.

- This strategy requires a fundamental change in corporate culture, as well as understanding of the importance of cooperation & teamwork between management and the work force.

- The results of this approach do not necessarily require cutting back to resources, rather it aims at continually improving the efficiency & profitability of the company, by removing all waste from the operations and by dealing with problems right away.

Agile Manufacturing (AM) is a term indicating the implementation of the principles of LP on a broad scale:

- The principle behind AM is ensuring agility (hence flexibility) in the manufacturing enterprise, so that it can respond quickly to changes in product demand and in customer needs.

- This flexibility is to be achieved through people, equipment, computer hardware and software, and sophisticated communications Systems.

- These approaches require that a manufacturer benchmark its operations; this method entails understanding the competitive position of other manufacturers with respect to its own and then setting realistic goals for the future.

- Quality Assurance and Total Quality Management

- Product quality directly influences the marketability and consumer satisfaction.

- Traditionally, parts are inspected (after have been manufactured) to ensure that they meet specifications and standards such as dimensions, surface finish, and mechanical & physical properties.

- Practice now is to make quality built into product (through all stages) rather inspecting after a product is made. The objective should be to control processes, not products.

- Defective products can be very costly to the manufacturer, creating difficulties in assembly operations, requiring repairing in the field, and resulting in customer dissatisfaction.

- Product integrity is a term that can be used to define the degree to which a product

- is suitable for its intended purpose.

- responds to a real market need

- functions reliably during its life, and

- can be maintained with relative ease.

- Total quality management (TQM) and quality assurance (QA) must be the responsibility of everyone involved in the designing and manufacturing a product. The major goal is to prevent defects from occurring, rather than to detect and reject defective products after they are made, (at 6 sigmas defects are reduced to only 3.4 defects per million).

- Important developments in quality assurance include the implementation of experimental design: factors involved in a mfg process and their interactions are studied simultaneously.

- Global manufacturing and competitiveness let to the establishment of quality control methods. This resulted in the ISO 9000 standards series on Quality management and Quality assurance. A company registered for this product means that the company conforms to consistent practices as specified by its own quality system.

- Product liability: a product’s malfunction or failure may cause bodily injury (or death) and financial loss to a person or an organization. Laws are different from country to country. All those involved with product design, manufacture, and marketing must fully recognize the consequences of product failure (even if misused). Examples of products that may involve liability:

- A grinding wheel that shatters and blinds a worker.

- A cable that saps, allowing a platform to drop.

- Brakes that does not work because of failure of a component

- Electric and pneumatic tools without proper warnings.

- Human-factors engineering and ergonomics deals with human versus machine interactions and thus are important aspects of the design and manufacture of safe products. Examples include:

- An uncomfortable or unstable workbench or chair.

- A mechanism that is difficult to operate manually, causing back injury; and

- A poorly designed keyboard that causes pain to the user’s hand and arms after repetitive use.

- Global Competitiveness and Manufacturing Costs

- General Trends in Manufacturing

Polymers:

- Thermoplastics soften when heated (and eventually liquefy) and harden when cooled—processes that are totally reversible and may be repeated.

Examples of common thermoplastic polymers include polyethylene,

polystyrene, poly(ethylene terephthalate), and poly(vinyl chloride).

- Thermosetting polymers are network polymers.They become permanently hard during their formation and do not soften upon heating. Network polymers have covalent crosslinks between adjacent molecular chains.

Thus, the materials do not soften when heated.Crosslinking is usually extensive, in that 10 to 50% of the chain repeat units are crosslinked.

Thermoset polymers are generally harder and stronger than thermoplastics and have better dimensional stability. Most of the crosslinked and network polymers, which include vulcanized rubbers, epoxies, and phenolics and some polyester resins, are thermosetting.

Example 1.1 Paper clips (mfg product):

Example 1.1 Paper clips (mfg product):

Designers would spend considerable effort and time in analyzing components and preparing detailed part drawings.

Designers would spend considerable effort and time in analyzing components and preparing detailed part drawings.

Casting: expendable mold & permanent mold (see Fig. 1.7a)

Casting: expendable mold & permanent mold (see Fig. 1.7a)

First a model of the sunglass is modeled using a CAD software package. The geometric information is sent to CNC milling machine.

First a model of the sunglass is modeled using a CAD software package. The geometric information is sent to CNC milling machine.